Ergonomics is a factor that is rarely taken into consideration within a company, yet its impact on a team's efficiency is tangible and real. To identify areas for improvement at each workstation, consider calling on the expertise of Pactisoud's teams.

Why invest in workstation ergonomics?

Pactisoud offers a free study of your workstations to improve their ergonomics.

Shift work can lead to MSD if certain rules are not followed.

Thanks to the expertise of our team, we can offer you solutions for adapting your working environment.

The primary objective is to protect the health of operators in their daily tasks. Sometimes we also manage to increase productivity while reducing the risk of accidents. In other cases, we can adapt the workstation to an employee's disability.

Don't hesitate to contact us to make an appointment!

How does the audit of your workstation work?

To give you an idea of the work carried out by our Pactisoud teams, here's how one of our latest audits was carried out for one of our customers.

Observing, calculating the rate and listening to the operator.

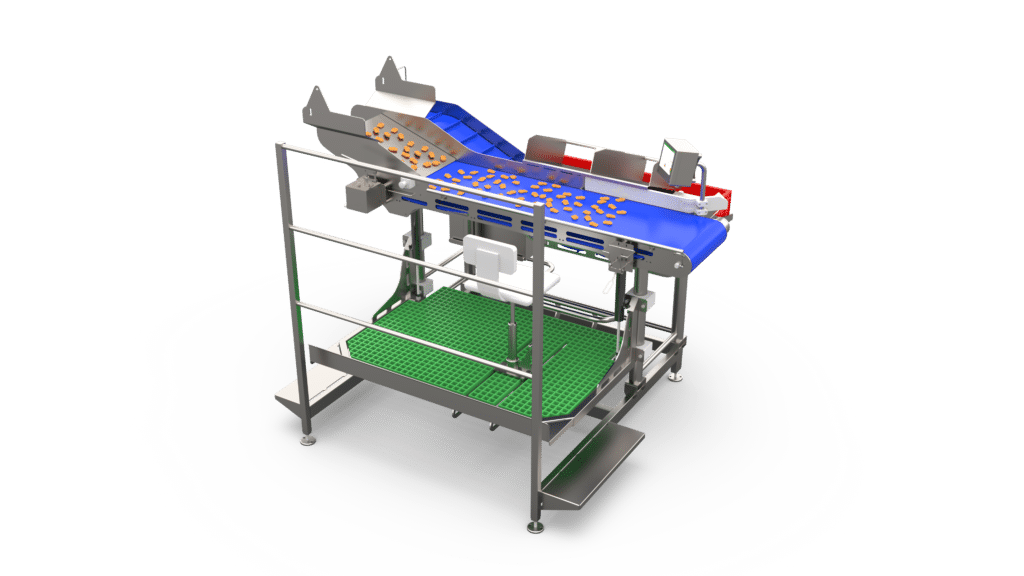

During the audit carried out by our team, we took an interest in the output of a cartoner.

The operator works at a manual workstation where cartons are packed. The operator prepares a batch of 5 products, takes a case, arranges the products in the case and then opens it to place it on an exit conveyor. The operator's workstation has his back to the product flow.

Answer provided by our audit

Following our findings, several areas for improvement were suggested in our audit report:

- Modification of the layout of the workstation, so that the operator can see the front of the line. This enables the operator to prepare himself in the best possible conditions to receive the products.

- The infeed conveyor is powered by a variable speed drive. We send it a high and low speed setpoint to create batches of 5 products on top of each other. The operator can now pick up the 5 cartons in a single movement.

- The ergonomic workstation has been redesigned so that the operator no longer has to lift products.

- The addition of a box conveyor with a stop eliminates the need to handle full boxes.

In this situation, the request for an audit proved invaluable, both in terms of health and productivity. Following the modifications, the customer was able to confirm that the workstation was no longer a source of MSDs. Operator handling has been reduced. There is no longer any load-bearing.

As a result, the packaging line can now run at a slightly higher speed than before, with far fewer line stoppages due to the boxing station.

Why should you call on Pactisoud for an ergonomic audit of your workstations?

As a specialist in the design and manufacture of equipment for process and packaging lines, Pactisoud excels in creating safe, comfortable and efficient working environments for your operators.

By working on this equipment, our team has acquired real expertise in ergonomic workstations, expertise that is now offered in the form of a free audit.

Once we have defined the areas for improvement on your workstations, Pactisoud is able to offer you tailor-made solutions that meet your needs.

Request your free audit now

Book your audit with our specialists now: fill in the contact form below and our sales department will get back to you as soon as possible to give you more details and arrange a meeting.