Palletising cobots

Automating the end of the production line is now a strategic challenge for manufacturers. With labour shortages, repetitive tasks and the need to increase production rates, the cobot palletiser is emerging as a high-performance, flexible and easy-to-deploy solution. ET PACK supports you in this transition with collaborative systems designed to integrate easily into your existing production environment, without requiring a complete overhaul of your line.

Why install a palletising robot on your line?

Le cobot palletiser combines the strength of an industrial robot with the flexibility of human-machine collaboration. Unlike a traditional robot, it does not require a safety enclosure in many cases, making it ideal for fluid interaction with operators. It takes on the most physical and repetitive tasks, reducing the risk of MSDs (musculoskeletal disorders) and improving working conditions.

This type of robot considerably increases the productivity by maintaining a constant pace, without tiring or slowing down. It ensures fast, consistent and reliable palletisingThis frees up time for operators, who can concentrate on higher value-added tasks. The result: your logistics flows are optimised, your costs reduced and your responsiveness enhanced.

How does a cobot palletiser work?

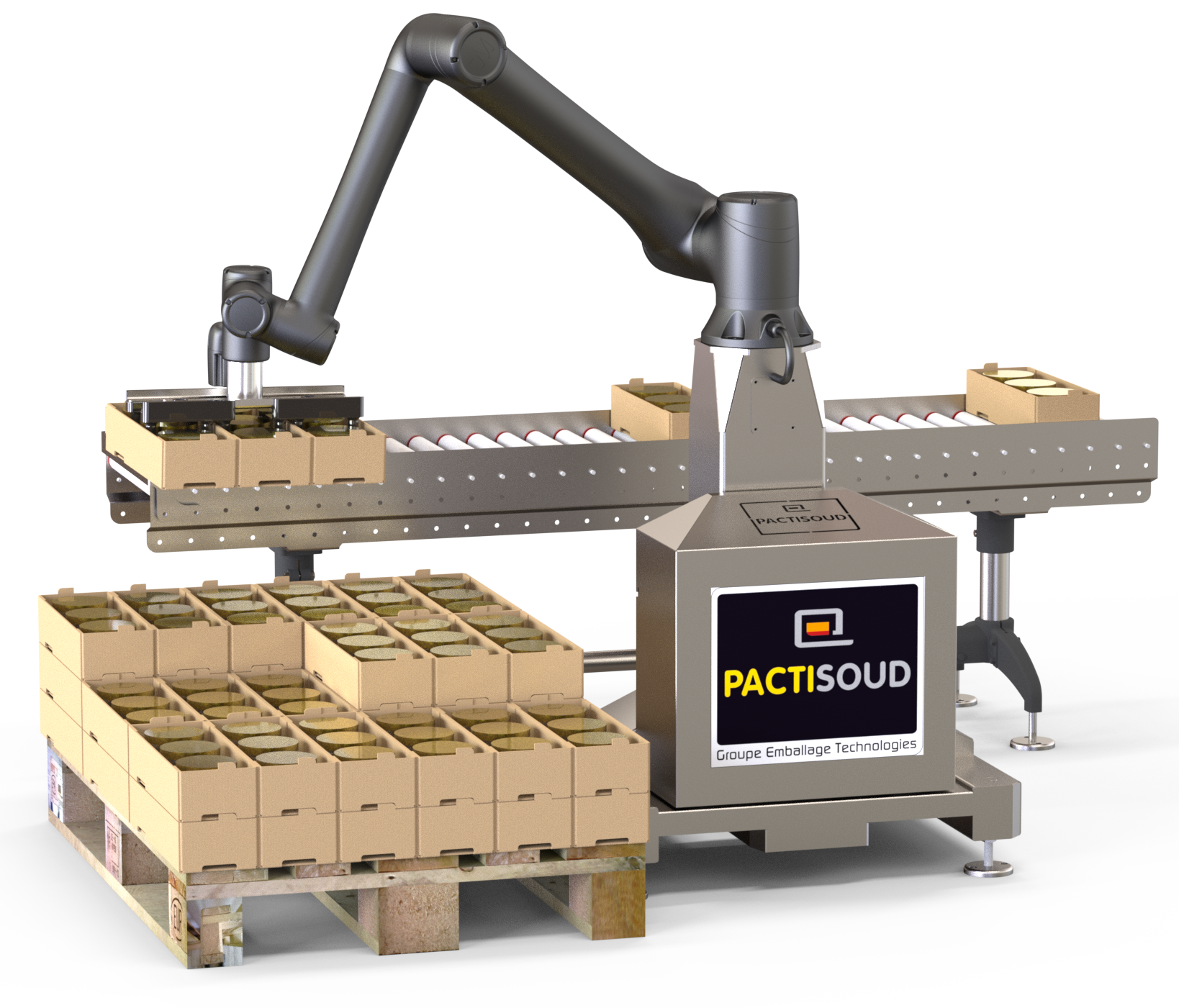

A cobot palletiser, such as the Dobot CR20A offered by ET PACK, is based on a modular architecture made up of the following components:

- A collaborative robotic arm (up to 20 kg payload) with a reach of 1,700 mm, designed to cover large working areas.

- An extendable lifting shaft up to 900 mm for palletising heights of up to 2,100 mm.

- A vacuum gripping systemIt can handle cartons, trays and glass containers with precision.

- A pallet detection systemwhich identifies the presence and correct positioning of the pallet before each deposit cycle.

- An intuitive software suitewith 3D visualisation, drag-and-drop configuration, automatic trajectory generation and customisable stacking patterns.

The whole system can be installed in less than 30 minutes, without any complex programming. The solution can be integrated into your existing line without any major modifications, making it easy to install. rapid deployment in all types of industrial environments.

What products can a cobot palletiser handle?

Cobot palletisers are designed to handle a wide variety of products, whatever their nature and packaging. They can handle :

- Cardboard boxes of different sizes and weights, including with labels oriented as required.

- Metal containersThese are robust but sometimes slippery, thanks to high-grip grippers.

- Glass containerswhich require precision, delicacy and control of suction force.

Thanks to an advanced gripping system (single or double suction), the cobot can adapt its speed and handling method according to the characteristics of the product. Functions such asinserting dividers or thecustom stacking guarantee optimum pallet stability for safe transport and storage.

The advantages of cobot palletisers

Opt for a cobot palletisermeans choosing a tool that is both powerful, safe and compact. Here are the main advantages:

- Ease of use The cobot is controlled via a user-friendly interface, accessible even without robotics skills.

- High security CE, SGS and RoHS certified, it is designed for safe operation alongside operators.

- Space saving Its compact design makes it easy to fit into tight spaces without changing the existing layout.

- High speeds With up to 13 cycles per minute and the ability to pick two products simultaneously, palletising is a breeze.

- Flexibility Simplified line changeover thanks to its forklift-transportable base and adaptable software configuration.

- Simplified maintenance Remote diagnostics, user training, 24/7 support, spare parts... everything is provided to guarantee continuity of your production.

Request a quote for the installation of a cobot palletiser

At ETPACK, we put our expertise at the service of your automation projects. Thanks to our partnership with Dobot Robotics, we can offer you robust, reliable and scalable collaborative palletising solutions. Our teams will support you from the feasibility study right through to commissioning, with a clear objective: to offer you a rapid and sustainable return on your investment.

Whether you're producing small batches or multiple SKUs, we've got a solution to suit your line. Contact us today to receive your personalised quote and find out how the cobot palletiser can transform your end of line.