In an industrial context where every square metre counts, optimising the space available in your factory is becoming a major issue. Modern production lines require intelligent conveyor solutions that can adapt to different timing constraints. This is precisely what flow management conveyors offer, a technology in which Pactisoud has developed in-depth expertise over more than 30 years.

What is a flow management conveyor and why do you need one?

A flow management conveyor is industrial equipment designed to reference, route and direct products on a production line with precision. The operation of packaging machines often involves different product rates - in-line, accumulated, step-by-step - which require appropriate solutions.

Flow management takes different forms depending on the nature of the products transported:

- Boxes

- Tills

- Ready-to-sell packaging

- Bottles

- Other specific packaging

Whatever your industry, the right conveyor solution can significantly optimise the efficiency of your production lines while maximising the use of available space.

The advantages of flow management conveyors for your production

Simplified installations and enhanced safety

In many cases, a specific conveyor can do away with complex equipment such as grouping stars, flippers or other pneumatic mechanisms. This simplification brings two major advantages:

- Increased security the absence of mechanical elements eliminates potentially dangerous re-entrant points

- Reduced maintenance fewer pneumatic systems means fewer interventions and lower maintenance costs

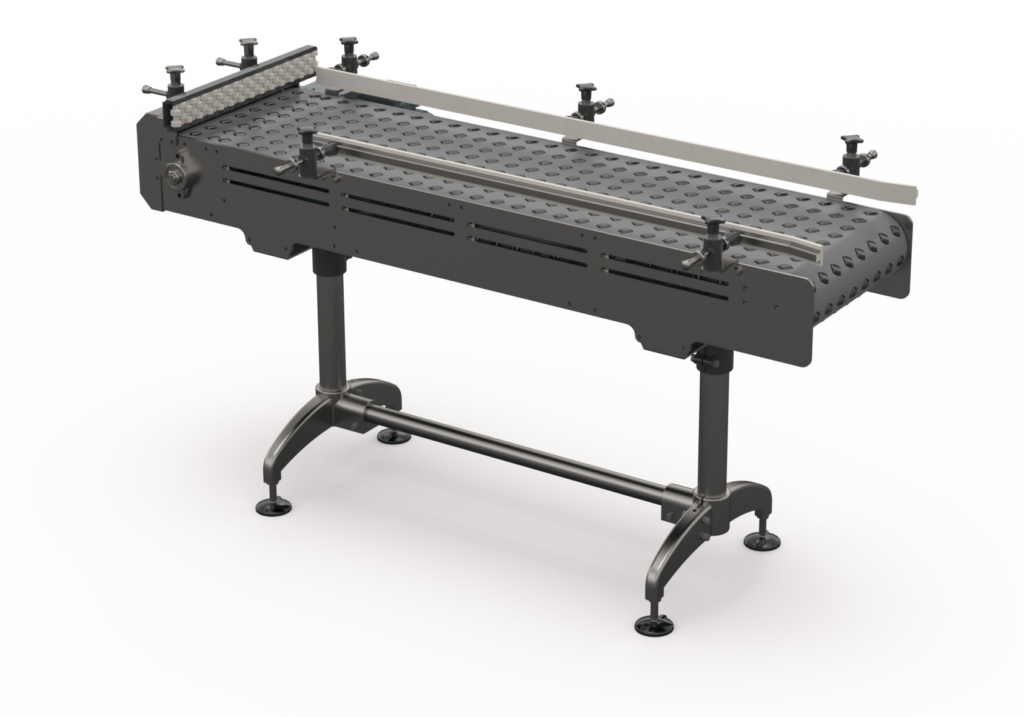

Pressure-free accumulation thanks to modular roller belts

One of the major innovations in this field is modular roller belts, which allow accumulation without pressure. This system offers a number of advantages:

- Increasing the number of products upstream of a machine

- Preservation of the integrity of the products, which are not damaged during storage

- Smooth management of variable speeds between different machines

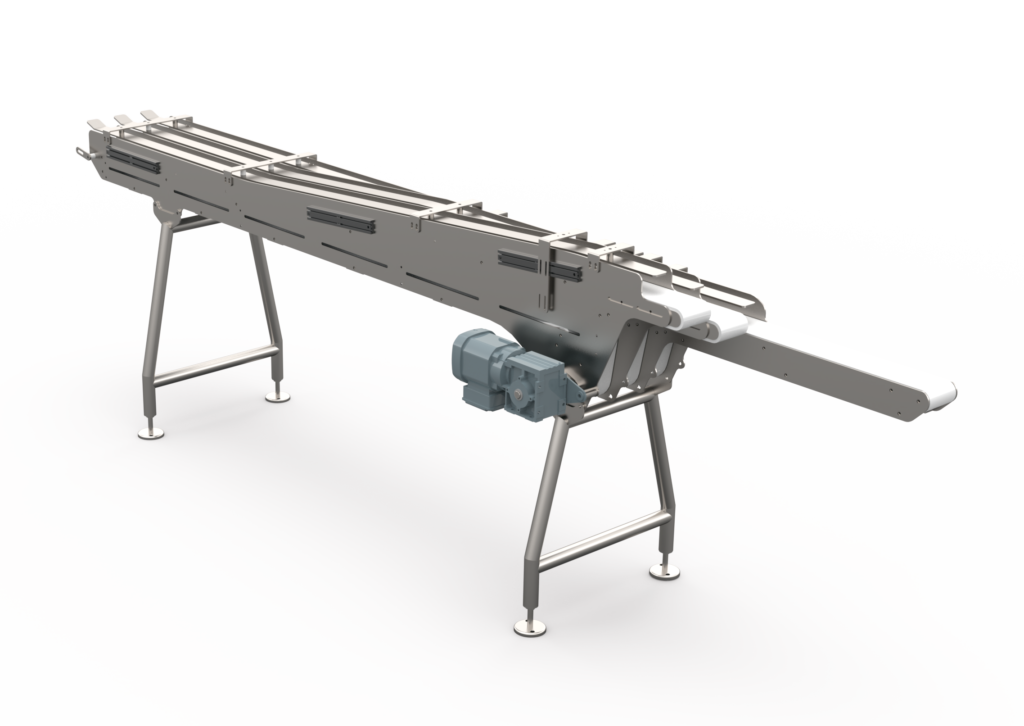

Optimised transfers with oriented roller conveyors

Oriented roller conveyors are another particularly effective technical solution for :

- Perform 90° transfers without the need for edge adjustments

- Return products as required by the process

- Reference products in a very small space

These technical features enable you to make the most of every square centimetre of your plant, while keeping your production running at optimum speed.

Why choose Pactisoud for your conveyor solutions?

Over more than three decades, Pactisoud has developed unrivalled expertise in the field of industrial conveying. This in-depth experience has enabled us to solve a multitude of varied problems in many industrial sectors.

Our team of specialist engineers analyse your specific needs to design the conveyor solution best suited to your production environment.

We take into account :

- The nature of your products

- Your plant's spatial constraints

- Speed requirements

- Interfaces with your existing equipment

- Safety standards applicable to your sector

Every installation is unique, and our customised approach ensures that your solution is perfectly aligned with your productivity and efficiency objectives.

Optimise your production line now

Don't let space constraints limit your productivity. Pactisoud's flow management conveyors allow you to optimise every square metre of your factory while improving the fluidity and efficiency of your production lines.

Our specialists are on hand to help you engineer your process and packaging lines. Contact us today to benefit from our expertise and find out how our solutions can transform your production environment.

Pactisoud - Innovation at the service of your productivity for over 30 years.