In an industrial context where efficiency and productivity have become major issues, palletising robots are becoming an essential solution for companies wishing to optimise their supply chain. Palletising robots are specifically designed to fully automate end-of-line operations, offering a complete, high-performance solution for handling heavy, repetitive loads.

What is a palletising robot?

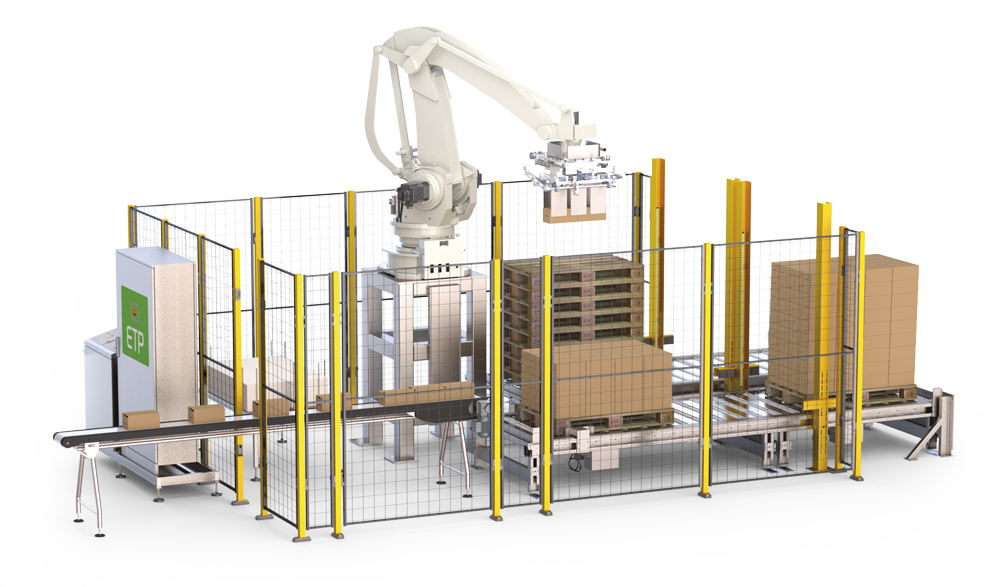

A palletising robot is automated equipment designed to stack products, boxes or crates on pallets according to a predefined pattern. This type of industrial robot is highly accurate and has a high load capacity, making it possible to optimise storage space while guaranteeing the stability of the pallets formed.

These robots are characterised by their sturdiness, speed of operation and ability to handle heavy loads of up to several hundred kilograms. Equipped with specific grippers (suction cups, grippers, forks), they can be adapted to all types of products and packaging, whether cartons, bags, crates or specific containers.

The strategic advantages of palletising robots

Maximised productivity and profitability

The integration of a palletising robot into your production line can significantly increase your operational rate. Capable of operating 24/7 without interruption, the robot maintains a constant rhythm and eliminates downtime caused by operator fatigue or breaks. This automation means an immediate increase in productivity, with speeds of up to several dozen cycles per minute depending on the model and application. The return on investment is generally rapid, often less than two years for the most optimised installations.

Enhanced safety and reduced RSI

By taking on heavy, repetitive handling tasks, palletising robots eliminate the risk of musculoskeletal disorders (MSDs) among operators. These pathologies, which are common in logistics environments, represent a considerable cost for companies, both in terms of absenteeism and loss of productivity.

The overall safety of the working environment has also been improved, with high-risk operations now entrusted to machines specially designed for these tasks. The robotised cells are equipped with safety devices that comply with current standards (immaterial barriers, zone scanners, emergency stops), guaranteeing optimum protection for personnel.

Quality and consistency of palletising

The precision of our palletising robots ensures consistent quality of products. pallets made upThis eliminates human error and guarantees optimum load stability. This consistency means less damage during transport and storage, limiting the financial losses associated with damaged products.

The traceability of operations is also facilitated, as every movement of the robot is recorded and can be analysed, enabling continuous improvement of processes and rapid detection of any anomalies.

A solution for all industrial sectors

Palletising robots are used in a wide range of sectors:

- Food industry handling fresh, frozen, packaged or bulk products

- Pharmaceuticals strict hygiene standards and complete traceability

- Logistics and e-commerce managing large and variable flows

- Manufacturing industry Handling heavy and bulky parts

- Chemicals and cosmetics Safe handling of sensitive products

Whatever the nature of your business, palletising robots can be adapted to your specific requirements and integrated seamlessly into your existing production environment.

Integrating a palletising robot: a structured approach

The implementation of a robotised palletising solution follows a rigorous process:

- Feasibility study : analysis of your needs, constraints and production environment

- Made-to-measure design developing a solution tailored to your specific needs

- Installation and configuration : setting up the equipment and configuring the programmes

- Team training transferring skills for optimum use

- Monitoring and maintenance : long-term support to guarantee performance

This methodical approach guarantees successful integration and optimum use of your investment.

Advanced technologies to boost performance

Modern palletising robots benefit from the latest technological advances:

- Artificial intelligence automatic optimisation of palletising patterns

- 3D Vision precise product recognition and positioning

- Intuitive interfaces simplified control and accessible programming

- IoT connectivity remote monitoring and predictive maintenance

- Virtual simulation test and validate configurations without interrupting production

These innovations help to constantly improve the performance of palletising robots, making them ever more efficient and adaptable.

Why choose ETPACK for your palletising project?

ETPACK is the partner of choice for the integration of robotised palletising solutions. Our technical expertise, in-depth knowledge of industrial constraints and personalised approach enable us to design installations that are perfectly adapted to your specific needs.

Our sales and technical teams will support you throughout your project, from the initial study to commissioning, including training your staff. This proximity guarantees a turnkey solution that is both efficient and durable.

Investing in the future of your production

The integration of a palletising robot represents much more than a simple investment in equipment: it's a strategic transformation of your production tool, geared towards operational excellence and competitiveness.

By opting for an ETPACK robotised palletising solution, you are choosing performance, reliability and innovation. Our experts are at your disposal to study your project and offer you the solution best suited to your needs.

Don't wait any longer to optimise your end-of-line packaging and add a new dimension to your supply chain. Contact us today for a personalised study of your robotised palletising project.