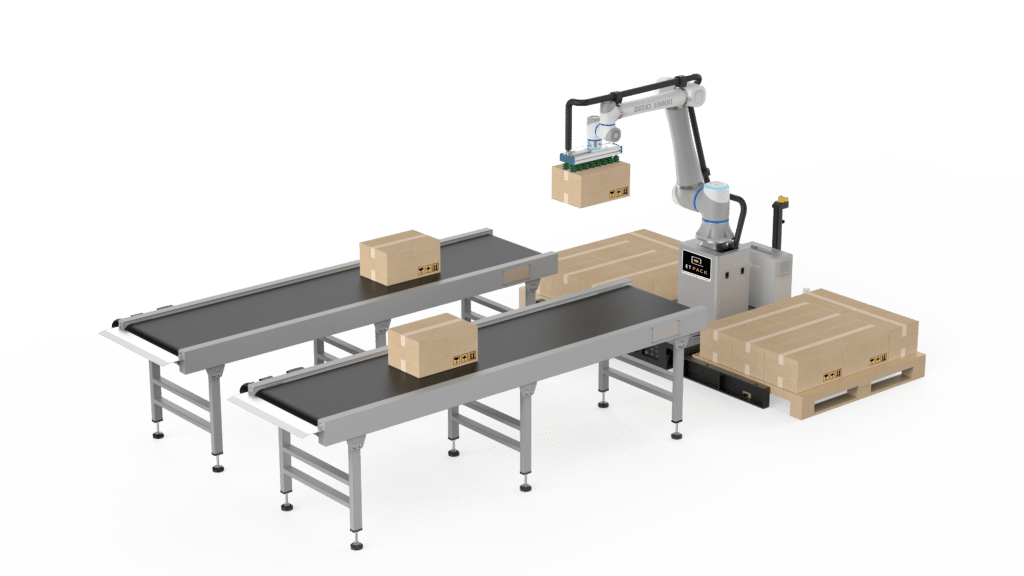

Working alongside your operators, the cobot saves you precious time when palletising products at the end of the line. Practical, easy to deploy and capable of adapting to a wide range of formats, the cobot is the perfect solution for preparing your pallets before dispatch.

Why opt for a cobot?

Installing a cobot at the end of a packaging line offers a number of advantages: space optimisation, mobility, flexibility in terms of possible formats, etc. The cobot meets a wide range of requirements.

Exceptional adaptability

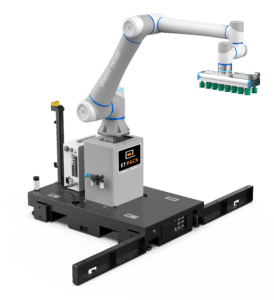

With a load capacity of up to 20 kg and a working range of up to 1,700 mm, the cobot is exceptionally efficient for palletising products. The machine is accompanied by a software platform that is simple and ergonomic to learn, using a teach pendant, a computer or an Android tablet.

A machine that can be moved easily

The cobot can be moved and reinstalled quickly and easily if required. The machine can be moved using a standard forklift truck. Its modular design means that the machine can be assembled in just 30 minutes once it arrives at its destination. Moving the machine also means no changes to the layout of the packaging line.

Saving valuable space

Optimising the space available is one of the main issues and challenges encountered on a production and packaging site. While a traditional palletising robot needs fencing and wire mesh to form a protective cage, a cobot does not. The absence of fences and wire mesh frees up valuable floor space in your working environment, while guaranteeing the safety of operators working in contact with the machine.

How a cobot works on your production line

The cobot requires the use of a single software platform, on which you control the palletising and grippers. You can act on several parameters, such as the stacking pattern or the movements made by the robot.

A 3D palletising simulation allows you to preview the results obtained by your configuration, so that you can identify potential problems without any repercussions or to optimise machine productivity.

Stacking patterns can be generated automatically by the cobot, to save time. Two suction modes are available to pick up one or two boxes, depending on your needs.

Increase productivity - add a cobot at the end of the packaging line

Our sales team and design office are at your disposal to help you improve your packaging line. Fill in the contact form below: we'll get back to you as soon as possible to discuss your requirements and provide you with the cobot best suited to your needs.