In the demanding world of food processing, every stage of production is crucial to guaranteeing a final product that meets hygiene, quality and yield standards. The flattening conveyor is an essential link in the processing chain, particularly for meat products. Its role? To effectively flatten the raw material to ensure uniform cooking, meticulous presentation and optimised packaging. Pactisoud, a specialist in industrial equipment, can help you choose and install high-performance flattening conveyors tailored to your production constraints.

Why install a flattening conveyor on your line?

L'installation of a flattening conveyor in a food processing line meets a number of industrial and health challenges. Firstly, the flattening of products - particularly meat - ensures greater uniformity in terms of thickness and density, a sine qua non for guaranteeing uniform industrial cooking.

How does a flattening conveyor work?

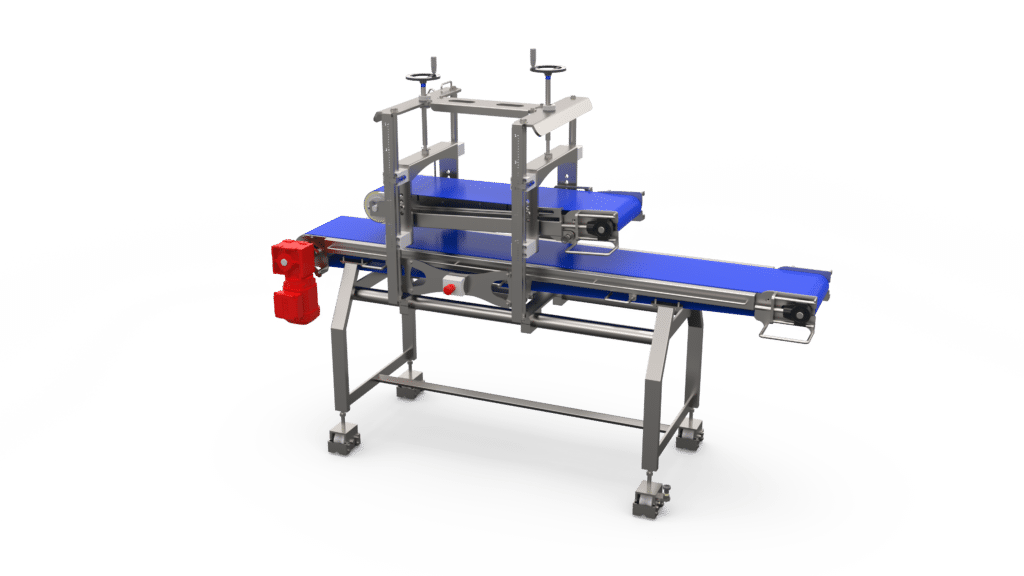

The operation of a flattening conveyor is based on a simple, but rigorously controlled principle: the material to be flattened (often raw meat or vegetable preparations) is conveyed on a conveyor belt over a conveyor belt. a motorised conveyor belt. A system of two conveyor belts, positioned one above the other, compresses the product in a controlled manner, to an adjustable pressure and thickness.

Modern flattening conveyors are designed to integrate easily into an existing line. They are generally made of stainless steel to comply with the latest hygiene standards in wet environmentsThey are equipped with quick-release systems for easy cleaning and maintenance.

The advantages of a flattening conveyor

The flattening conveyor offers many advantages for food manufacturers. Firstly, it enables the flattening stage to be carried out quickly and evenly, without variations in pressure or quality. This contributes directly to the overall efficiency of the production line.

By optimising the shape and thickness of the products, the conveyor ensures perfectly even distribution of the material in the packaging. This avoids empty zones or, on the contrary, overloading, which can lead to cooking defects or alter the appearance of the finished product. The result is a consistent, consistent end product that is visually enhanced.

In terms of ergonomics, the flattening conveyor considerably reduces the amount of work required. arduous work for operators. Tasks that used to be carried out manually - sometimes time-consuming, tiring and repetitive - are now automated. This automation also reduces the risk of musculoskeletal disorders (MSDs) and helps to improve working conditions on the production floor.

Finally, the conveyors offered by Pactisoud are designed for optimum reliability, with robust components, appropriate drive systems and seamless integration into the existing industrial environment.