In a competitive market, efficient and accurate labelling is essential to stand out from the crowd. Investing in advanced labelling solutions, such as ALTECH systems in collaboration with Sermatec, can transform your production line and strengthen your market position.

Why invest in a high-performance labelling solution?

In an industrial environment where speed and accuracy are essential, having a high-performance labelling system is a real asset. Reliable and accurate labelling is not just a question of regulatory compliance: it plays a key role in brand perception, logistics management and optimising your production processes.

Good labelling ensures that products are clearly and legibly identified, which is crucial for ensuring traceability throughout the supply chain. Whether for food, cosmetics, pharmaceuticals or chemicals, poorly applied or incorrect labelling can lead to costly product recalls and damage to your reputation.

By opting for an automated solution, such as ALTECH labelling systems, you reduce human error, improve production speed and standardise the quality of your labels. This means greater efficiency and less waste of consumables. What's more, these systems are designed to adapt to different formats and production speeds, ensuring optimum flexibility to meet the demands of your industry.

In short, investing in high-performance labelling equipment means securing your production, strengthening your brand image and optimising your costs over the long term.

The labelling systems offered by Sermatec

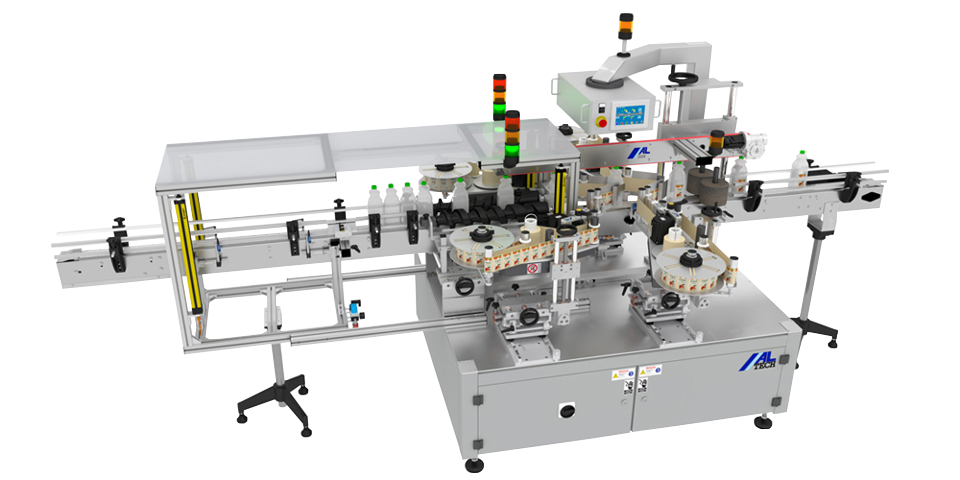

ALline E: double-sided labelling system

Designed to apply one or more labels to the front and back of elliptical or rectangular products, the ALline E is ideal for the food, cosmetics, chemical and pharmaceutical sectors. It can process up to 150 products per minute, depending on product and label dimensions. Its compact base is equipped with two opposing side label applicators from the ALritma series, all protected by a transparent enclosure for easy access.

Main features:

- Flexible handling with various types of conveyor (scale or belt).

- Spacing devices adapted to specific needs.

- Centralised synchronisation for accurate labelling, even at varying speeds.

- Possibility of labelling on one or more sides, including special configurations such as angled labelling or applying seals to caps.

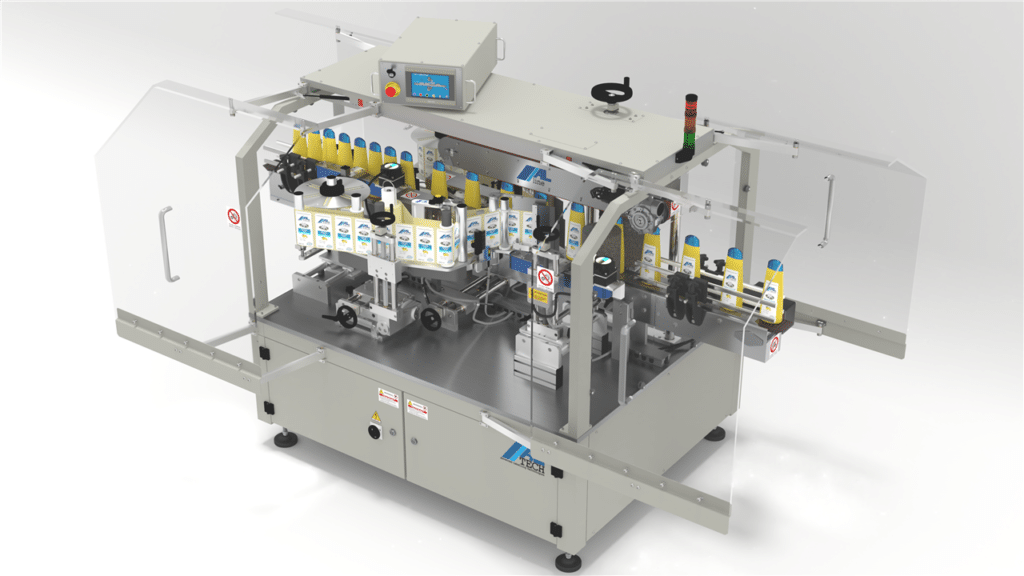

ALline C: Wrap-around labelling system

The ALline C is designed to apply wrap-around labels to cylindrical packaging such as jars, bottles and flasks in plastic, glass or metal. Suitable for use in the food, chemical, cosmetics and pharmaceutical industries, its performance ranges from 80 to 200 items per minute, and can reach 150 items per minute in certain configurations. Its solid, compact base can be fitted with automatic labellers from the ALstep or ALritma series, protected by an easy-access cabin.

Main features:

- Compatibility with various types of conveyor for product handling.

- Specific wrapping units for precise label application.

- Flexible configurations for partial or full labelling, in-phase labelling, applying seals and handling slightly tapered shapes.

- Intuitive micrometric adjustments for fast, accurate format changes.

Advantages of these labelling systems

- Flexibility: adaptable to a wide range of products and shapes, with customisation options to meet the specific needs of each industry.

- Precision: advanced technologies guarantee accurate label positioning, even at high speeds.

- Efficiency: increased production rate while reducing errors and waste.

- Ease of use: user-friendly interfaces and intuitive settings make it easy to learn and maintain.

- Technical support: professional assistance with technical consultancy, development of customised projects and maintenance of installations.

Request a quote for the installation of a labelling system

Fill in the contact form below: our sales team will get back to you as soon as possible to define your project and your requirements, and to offer you the solution best suited to your packaging line.