In the agri-food, cosmetics and pharmaceutical sectors, packaging automation has become essential for improving efficiency, consistency and competitiveness.

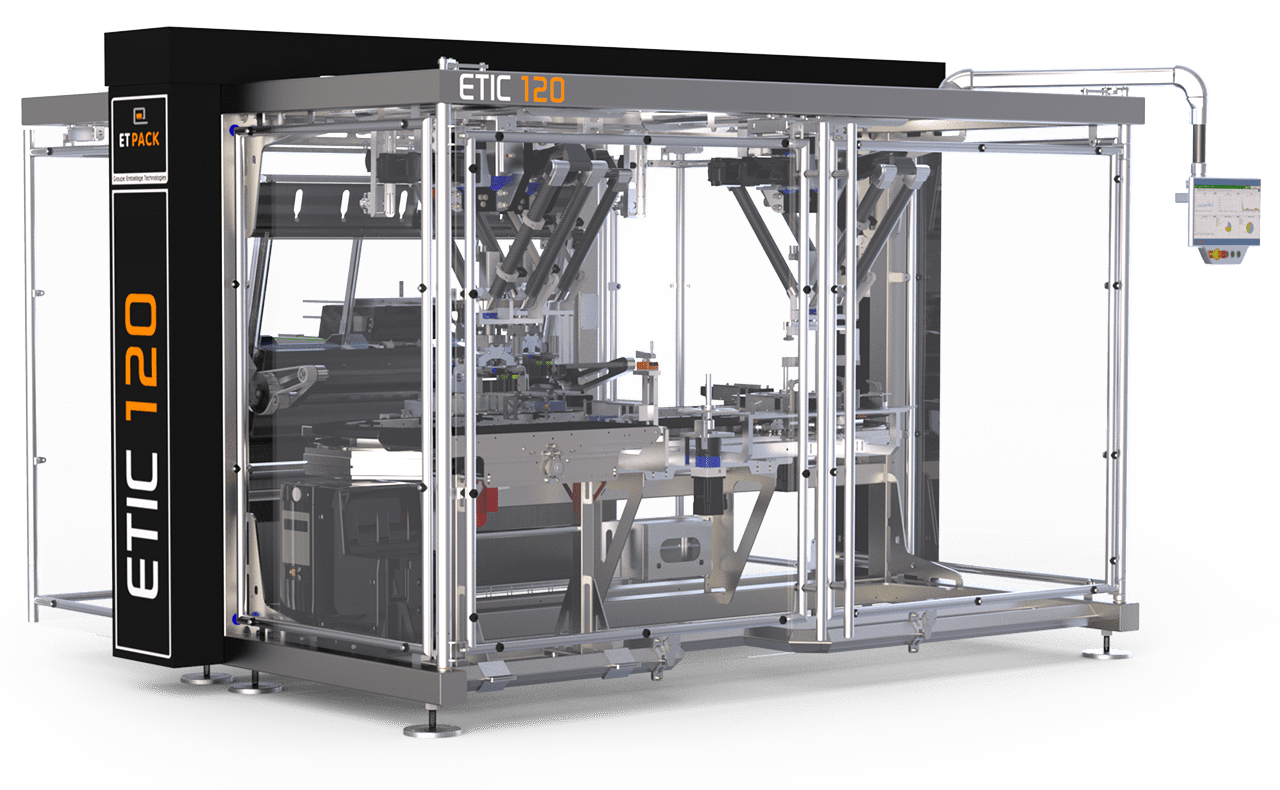

The robotic cartoner has established itself as a high-performance solution for fast, reliable secondary packaging that is perfectly suited to the requirements of manufacturers. At ETPACKWe design and install custom-built robotic cartoners capable of meeting the most demanding production requirements while guaranteeing impeccable packaging quality.

How does a robotic cartoner work?

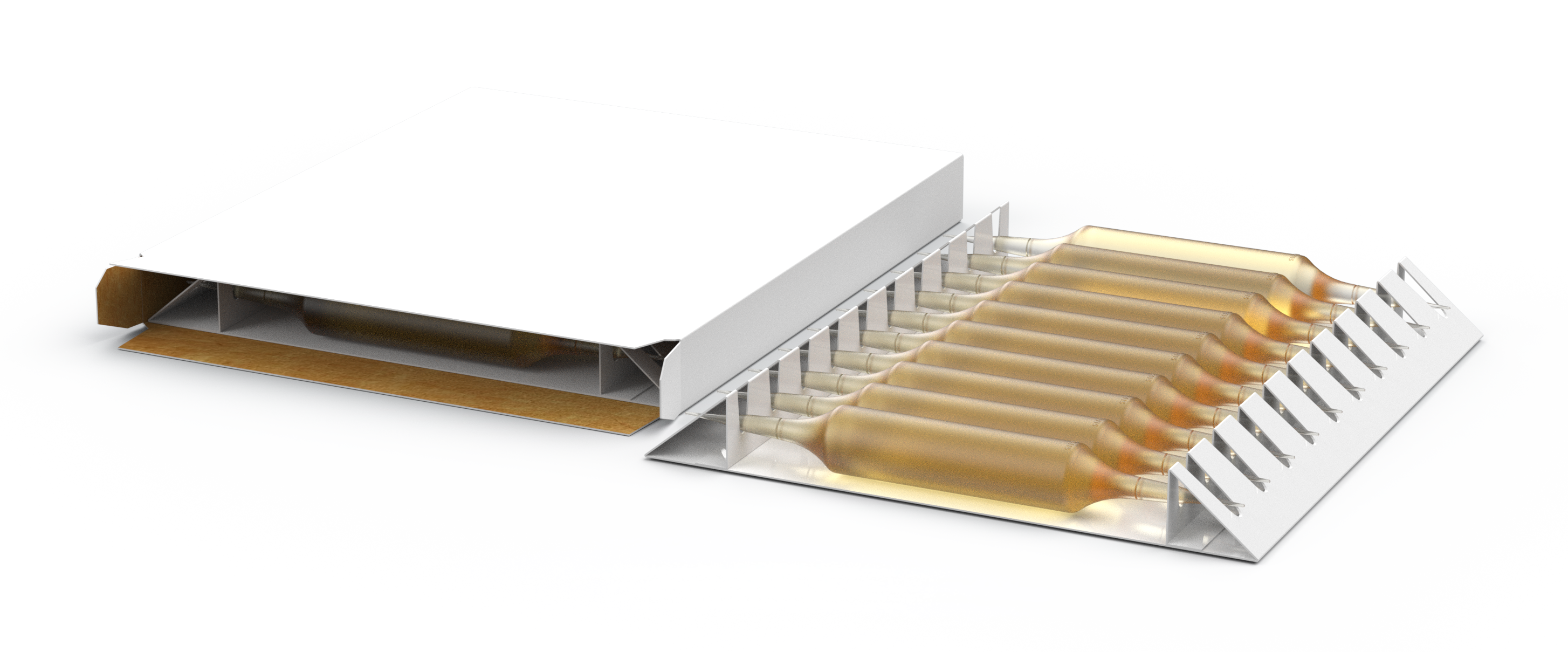

The robotic cartoner is a automated industrial machine for secondary packaging. Its main role is to place products (bottles, boxes, sachets, cases, etc.) in pre-formed cartons or cases. They are generally employed at the end of the production line, after the primary packaging of the product.

There are several stages in the process:

- Flat packs picked up in a dedicated shop.

- Opening the case, generally by a mechanical system or suction cups.

- Inserting the product(s) into the case using a robotic manipulator. This robotic arm, often with Cartesian axes or pick & place technology, guarantees high-precision product placement.

- Closing the caseby gluing, clipping or inserting a flap.

- Holster ejection to the rest of the line (checking, labelling, boxing, etc.).

Robotic cartoners designed by ETPACK incorporate the latest control and detection technologies to ensure smooth, safe operation at high speeds. Format changes can be simplified thanks to assisted or automated adjustment systems, promoting flexibility in production.

The advantages of robotic cartoners

Adopt a robotic cartoner in its production process offers a number of advantages:

- Increased productivity These machines can reach very high speeds, ensuring constant output over long periods. Manual handling is eliminated or greatly reduced, which reduces cycle times.

- Precision and consistency Thanks to automation, each case is formed, filled and sealed according to reproducible, error-free standards. This reduces rejects and improves the brand image of the final product.

- Versatility ETPACK's robotised cartoners are capable of handling a wide range of formats, sizes and materials. The same equipment can pack several product ranges, thanks to rapid format changes.

- Space saving The solutions developed by ETPACK are compact and can be easily integrated into existing production lines, even where space is limited.

- Safety and ergonomics Automation reduces the risk of musculoskeletal disorders for operators. What's more, the man-machine interfaces are designed to be intuitive and accessible.

What packaging formats can robotic cartoners handle?

The robotic cartoners are capable of handling a wide variety of packaging formats. They are particularly appreciated for their adaptability to different business sectors :

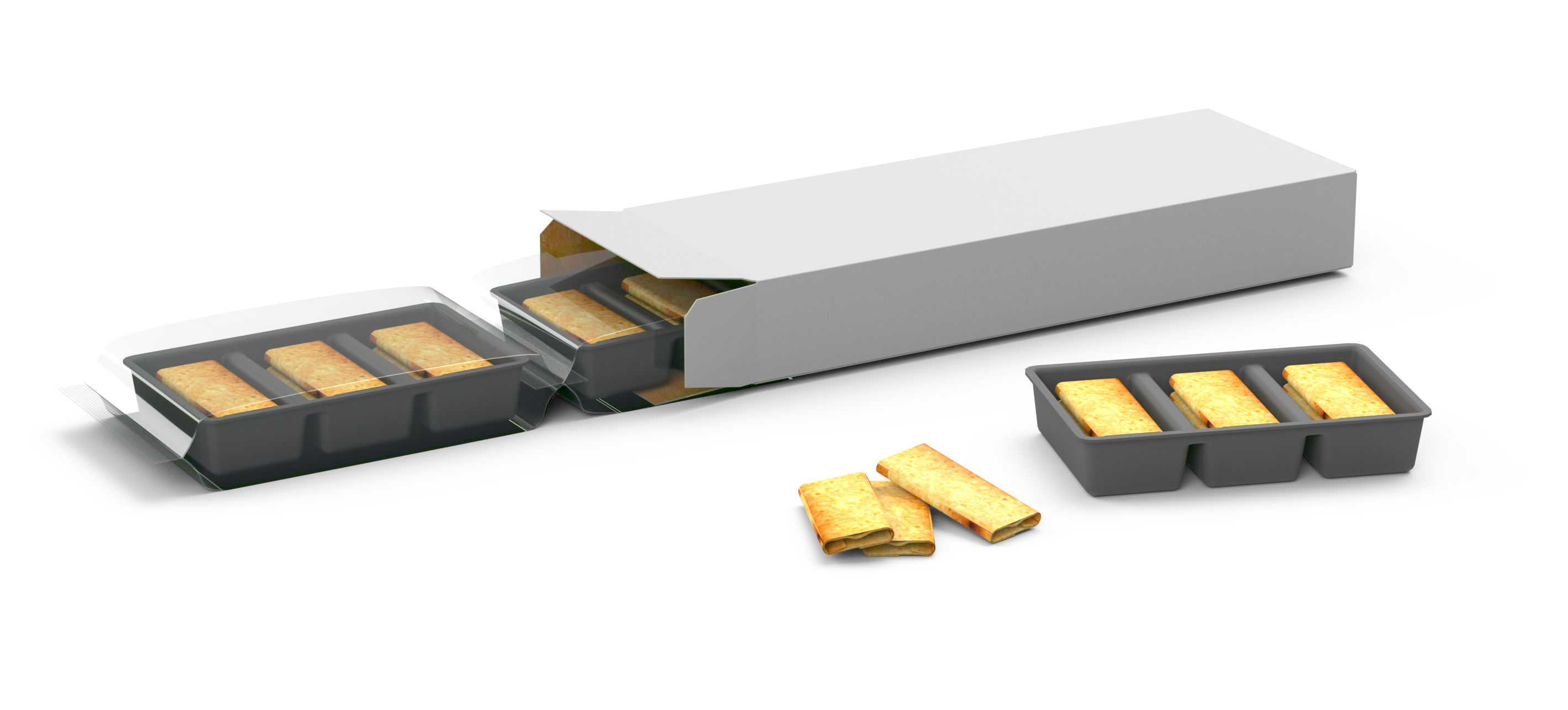

- Food industry Cereal boxes, bags of sweets, frozen foods, chocolate bars, biscuits... secondary packaging provides a neat presentation and extra protection, while facilitating logistics.

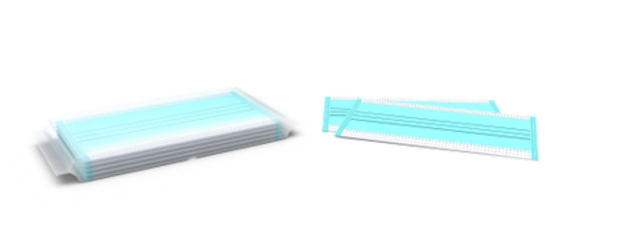

- Pharmaceuticals Packaging: bottles, blister packs, tubes of cream... the case ensures sanitary safety and essential regulatory traceability. Automatic labelling and control devices ensure compliance with the strictest standards.

- Cosmetics The aesthetics of packaging play a key role here. ETPACK cartoners ensure a clean closure and precise positioning of the product in its case, for an optimal customer experience.

Depending on requirements, the cartons can be single-closure, tab, window or reinforced. The machines can also handle eco-designed packaging made from recyclable cardboard, in line with companies' CSR objectives.