- Output up to 35 cans/min

- Casing from a flat cutout

- Intermittent operation

- Glued or clipped closure

Additional information

| Machine speed | |

|---|---|

| Final packaging | |

| Your product |

For manufacturers keen to optimise the stability and quality of their secondary packaging, the EcoWrap overwrapper with top gluing has established itself as a high-performance, reliable solution. Designed to meet the requirements of modern production lines, this packaging machine ensures neat and robust packing, adapted to a wide variety of formats. By combining mechanical precision, energy efficiency and high output, ETPACK's EcoWrap overwrapper with superior gluing offers an ideal compromise between productivity and finishing quality. Discover how this innovative technology can transform your packaging lines.

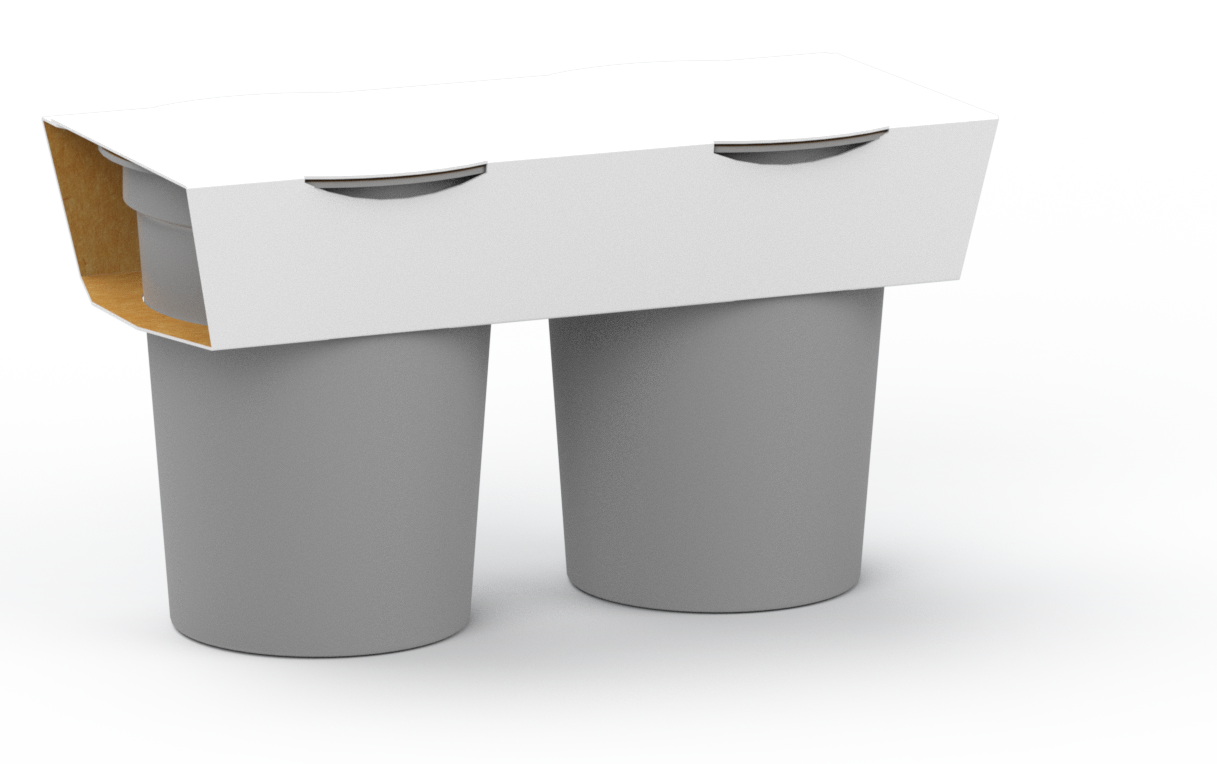

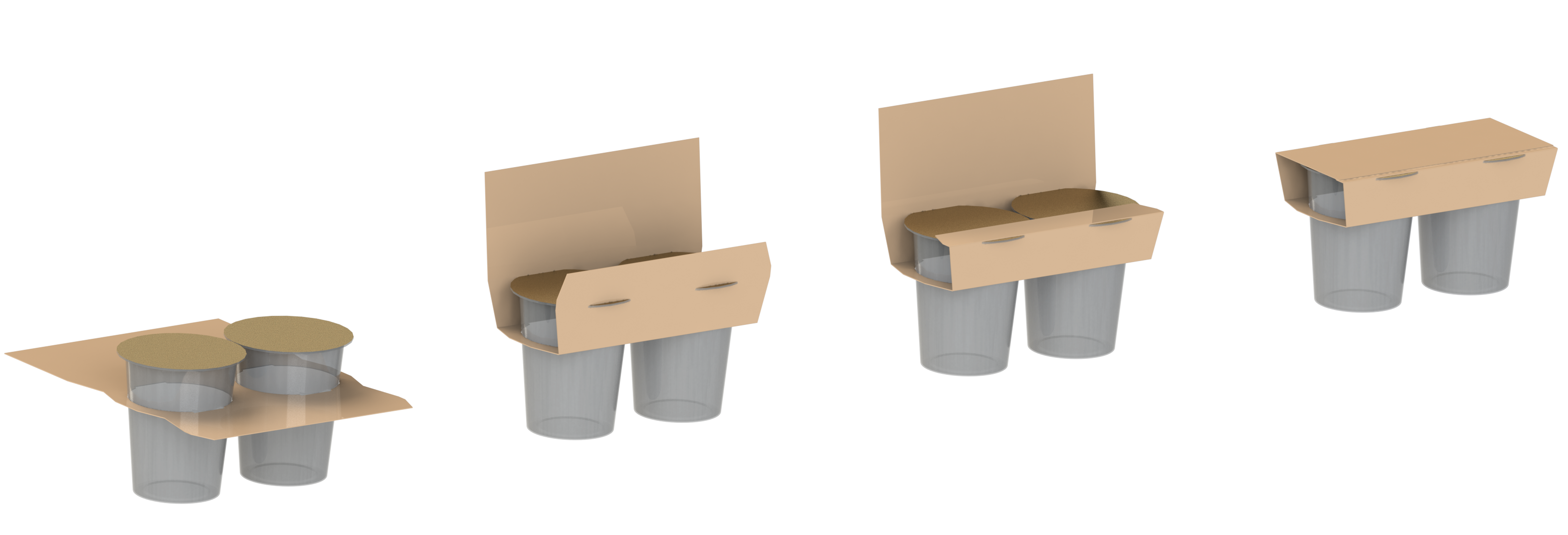

La EcoWrap overwrapper with top gluing is a machine designed to group several products together in a cardboard sleeve, ensuring that they are protected and held together during logistics. This technology is based on a secondary packaging process that begins with the automatic feeding of products. The products are pre-grouped and oriented according to customer specifications (by 3, 6, 12, etc.) before being transported to the forming area.

A pre-cut cardboard cover is then positioned over the batch. The system of top bonding comes into play at this stage: dots of hotmelt glue are applied to the top of the grouping, then the cap is applied with precision. Using a system of articulated arms or suction cups, depending on the model, the cap is folded down and pressed to ensure perfect adhesion. The whole assembly is held together without the need for glue on the sides or bottom of the pack.

The production rate can be adapted to the specific needs of each line. The ETPACK EcoWrap overwrappers are designed to integrate easily into a variety of production environments, with an intuitive control interface and quick adjustments for format changes. This type of overwrapper is compatible with different types of product: bottles, jars, cans, food cartons, etc.

Opt for a EcoWrap overwrapper with top gluingmeans choosing a packaging method that guarantees a high level of quality. excellent pack stability, particularly important in sectors where the stability of the finished product is paramount.

Le top bonding ensures that products are held together evenly, reinforcing their cohesion during handling, transport and storage. Unlike other packaging methods, which use side or bottom gluing, top gluing distributes the adhesive forces more evenly and prevents deformation of the pack, particularly in the event of temperature or humidity variations.

This technique is also particularly for palletising. By ensuring greater parcel homogeneity, it facilitates the creation of stable pallets, which reduces the risk of tipping during transfers. This contributes to a smoother, safer supply chain, with a significant reduction in loss or damage.

Another significant advantage: the reduced glue consumption. As the glue is only applied to the top cap, the volume of glue used is reduced without compromising the strength of the packaging. This is particularly interesting in terms of environmental and economic performance, reducing both the cost of consumables and the carbon footprint of the process.

Last but not least, the top-gluing system offers great flexibility when it comes to customising the packaging. Caps can be printed, die-cut or custom-marked according to the marketing or logistical needs of the user company. This makes them a particularly popular solution in the food, cosmetics and pharmaceutical sectors.

| Machine speed | |

|---|---|

| Final packaging | |

| Your product |