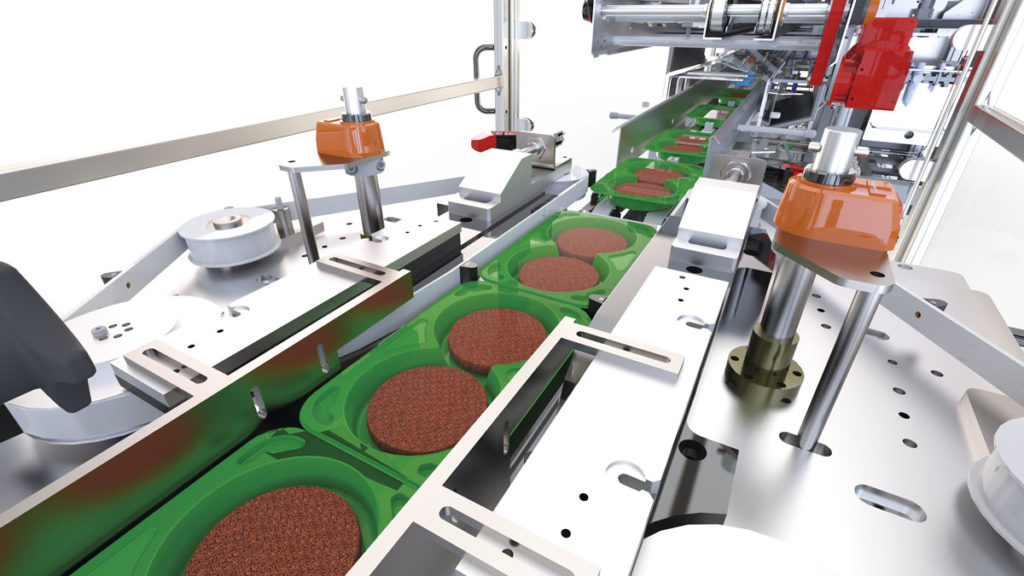

Accumulation and timing

GENERAL DESCRIPTION

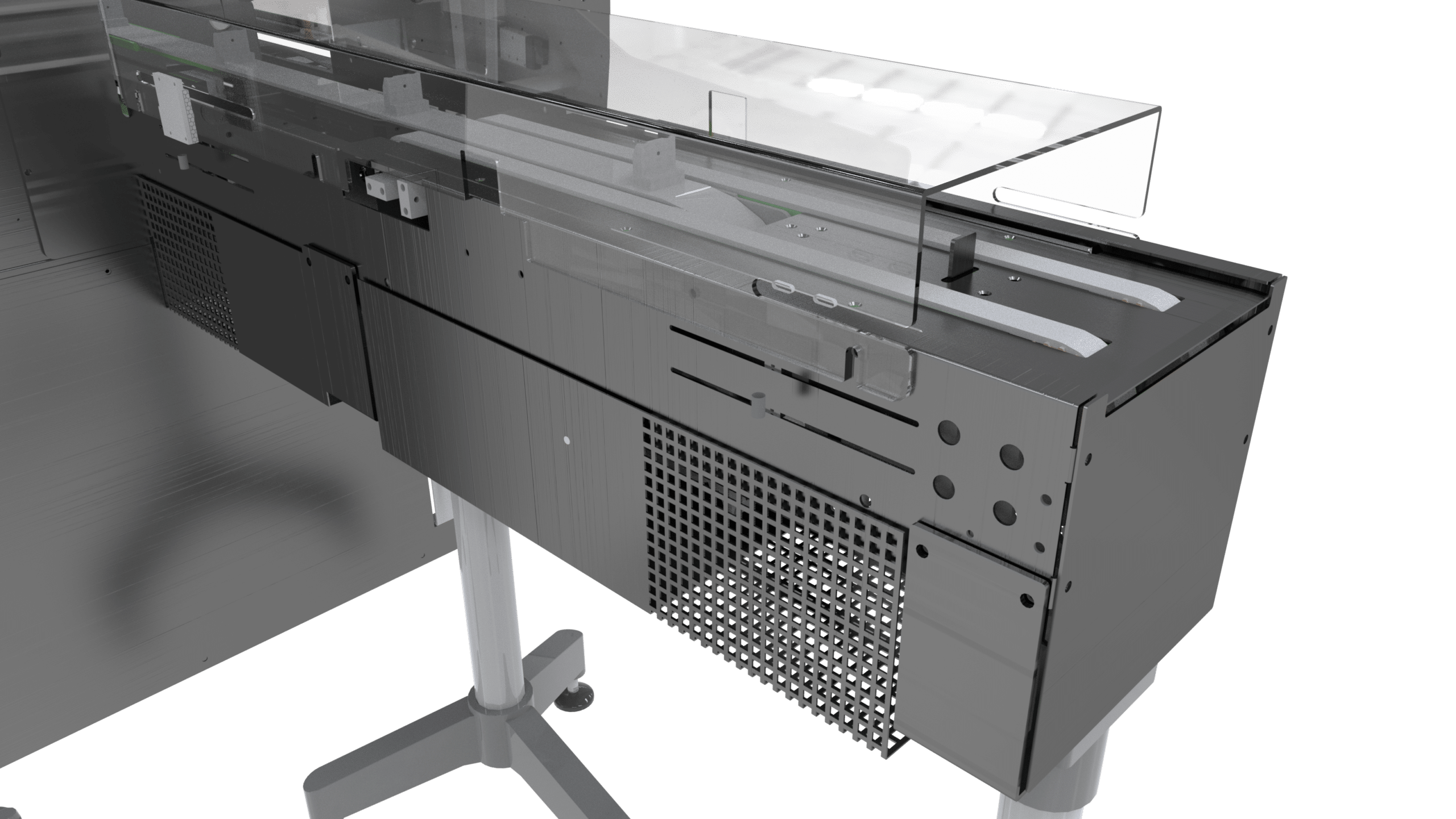

Accumulation and pacing allow you to manage variations in rhythm between upstream and downstream machines, while ensuring consistent product presentation for batching or final packaging. This guarantees continuous, controlled, smooth flow.

Le Emballage Technologies Group offers storage systems designed to absorb variations in output and avoid line stops. They allow products to be stored temporarily without direct contact or excessive pressure, thus preserving their integrity.

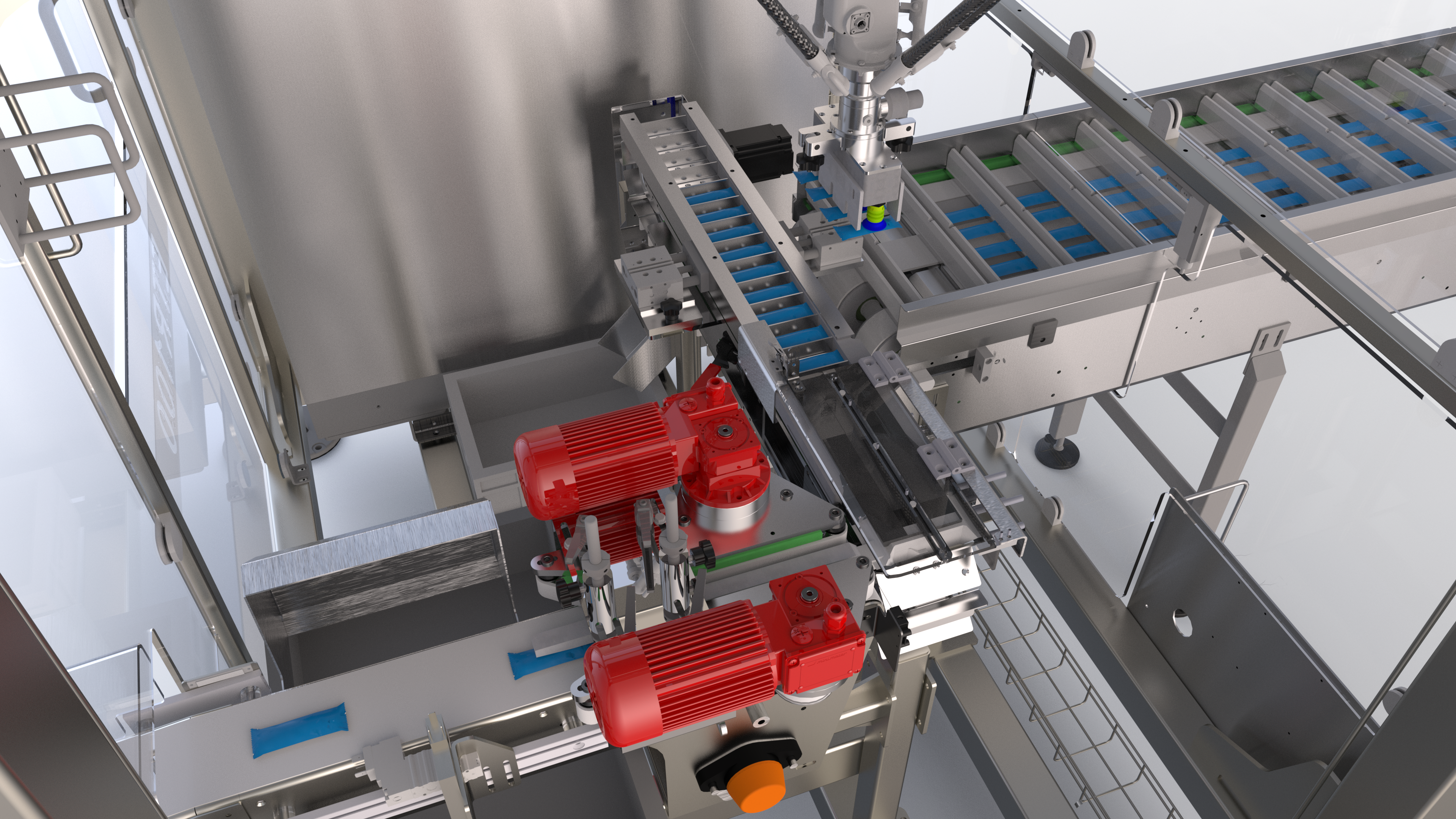

Le cadenceIt allows you to distribute products in a regular, synchronised wayThis is achieved by positioning them at constant intervals before feeding them into a collating, overwrapping or case-packing station. This equipment is compatible with a wide variety of formats and can be easily integrated into high-speed environments.

Thanks to accumulation and clocking, production lines are more efficient. stability, efficiency and productivityThis reduces manual handling and the risk of clogging.

TECHNICAL DATA

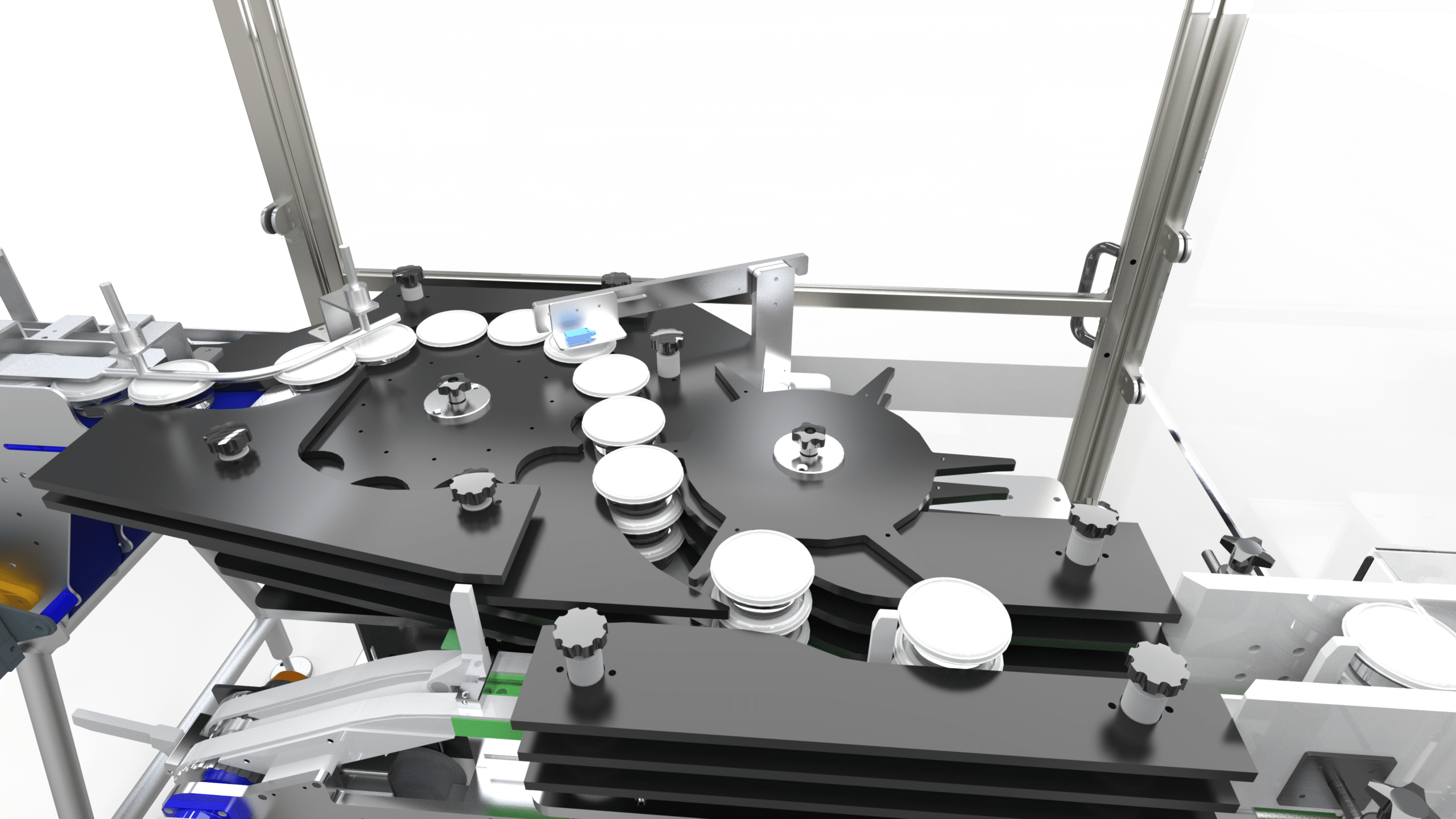

- 4 solutions for accumulating and timing your products: infeed with stop, infeed with belts, star infeed and infeed with robot.

- These power supplies adapt to your existing lines

- Sensors and cells to manage flow in real time

Additional information

In the same range

Related products

-

SE Line

- Integrated solutions, Labelling and marking solutions, Labelling

- Labeller with opposite side label applicators

- Output up to 200 parts/min

- Discover

Machine speed Final packaging Your product -

Bundling promotional packs

- Integrated solutions, Labelling and marking solutions, Labelling

- Output up to 250 products/min

- Discover

Machine speed Up to 250 cps/min

Final packaging Your product Cartons, Cases, Bottles, Pots, Sachets

-

Bundling promotional packs

- Integrated solutions, Labelling and marking solutions, Labelling

- Output up to 25 batches/min

- Discover

Machine speed Up to 45 batches/min

Final packaging Your product Cartons, Cases, Bottles, Pots, Sachets