Robots

In an industrial context where performance, safety and productivity have become major challenges, the automation of production lines is an essential solution. In this respect, the palletising robot plays a key role: installed at the end of the line, this palletising robot takes care of transferring, positioning and stacking products on pallets. This innovative technology is winning over an increasing number of manufacturers in all sectors, thanks to its ability to improve production rates, reduce risks for operators and guarantee perfect, uniform and safe palletising.

Why install a palletising robot on your line?

The first advantage of a palletising robot is a significant reduction in the number of palletising operations. musculoskeletal disorders (RSI) among operators. By taking on repetitive, heavy and potentially dangerous tasks, the palletising robot helps to protect the health of staff while reducing downtime caused by prolonged physical exertion.

But over and above the health aspect, these machines offer a considerable productivity gains. A palletising robot is capable of handling several cycles per minute, without interruption, with constant precision. This level of performance enables higher speeds to be achieved while limiting pallet positioning errors.

Finally, one of the other often underestimated advantages is optimising pallet space. Thanks to precise programming, the palletising robot perfectly adapts the layout of products according to optimised palletising patterns. This means better use of transported volume, lower logistics costs and greater load stability.

How does a palletising robot work?

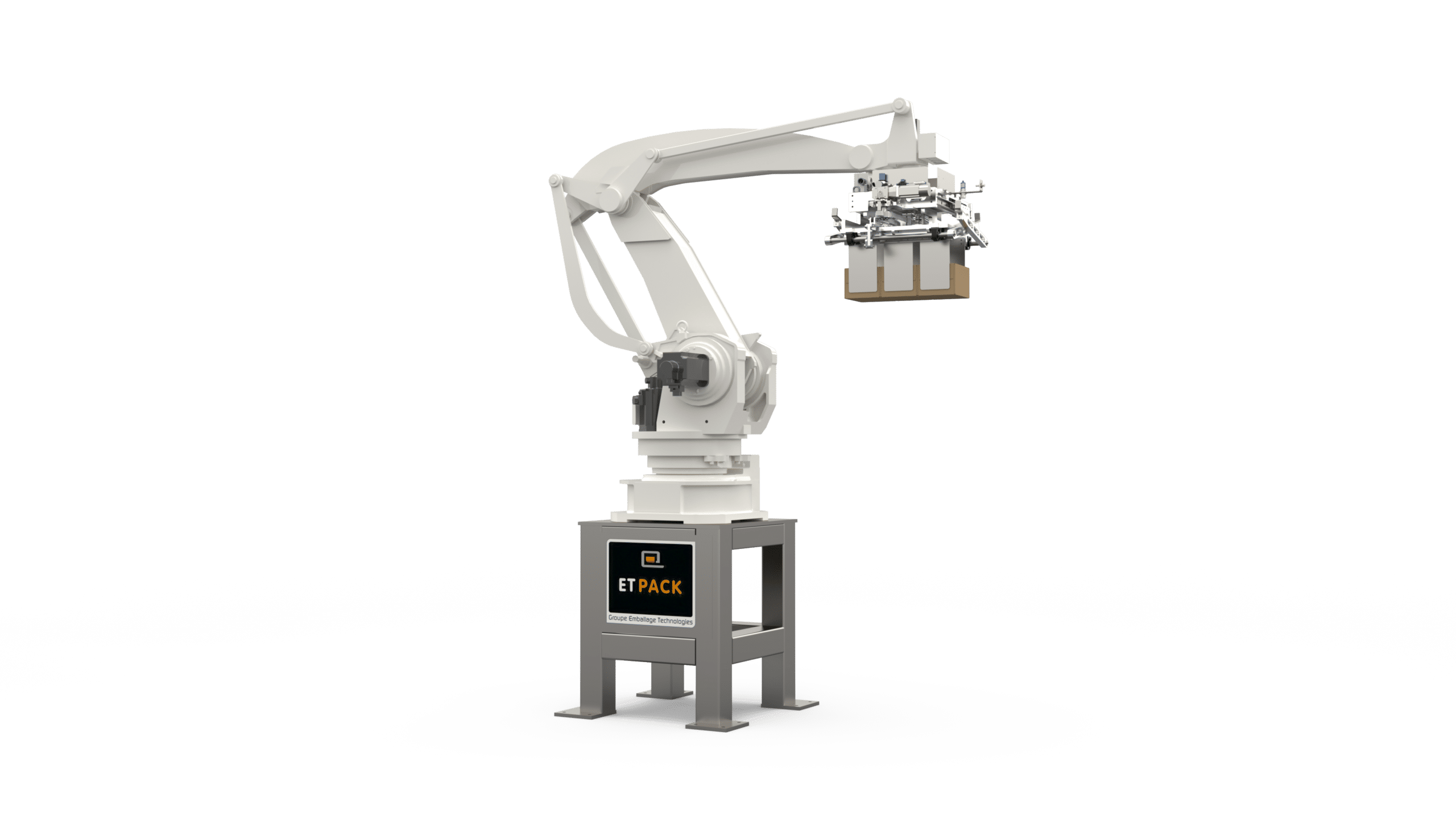

A palletising robot is generally made up of an articulated arm, which can be programmed according to the formats and speeds required. This arm is fitted with a gripper adapted to the type of product being handled (suction cups, grippers, forks, etc.). The products arrive on a conveyor, are detected by a vision system or sensors, then precisely gripped and placed on the pallet in a defined pattern.

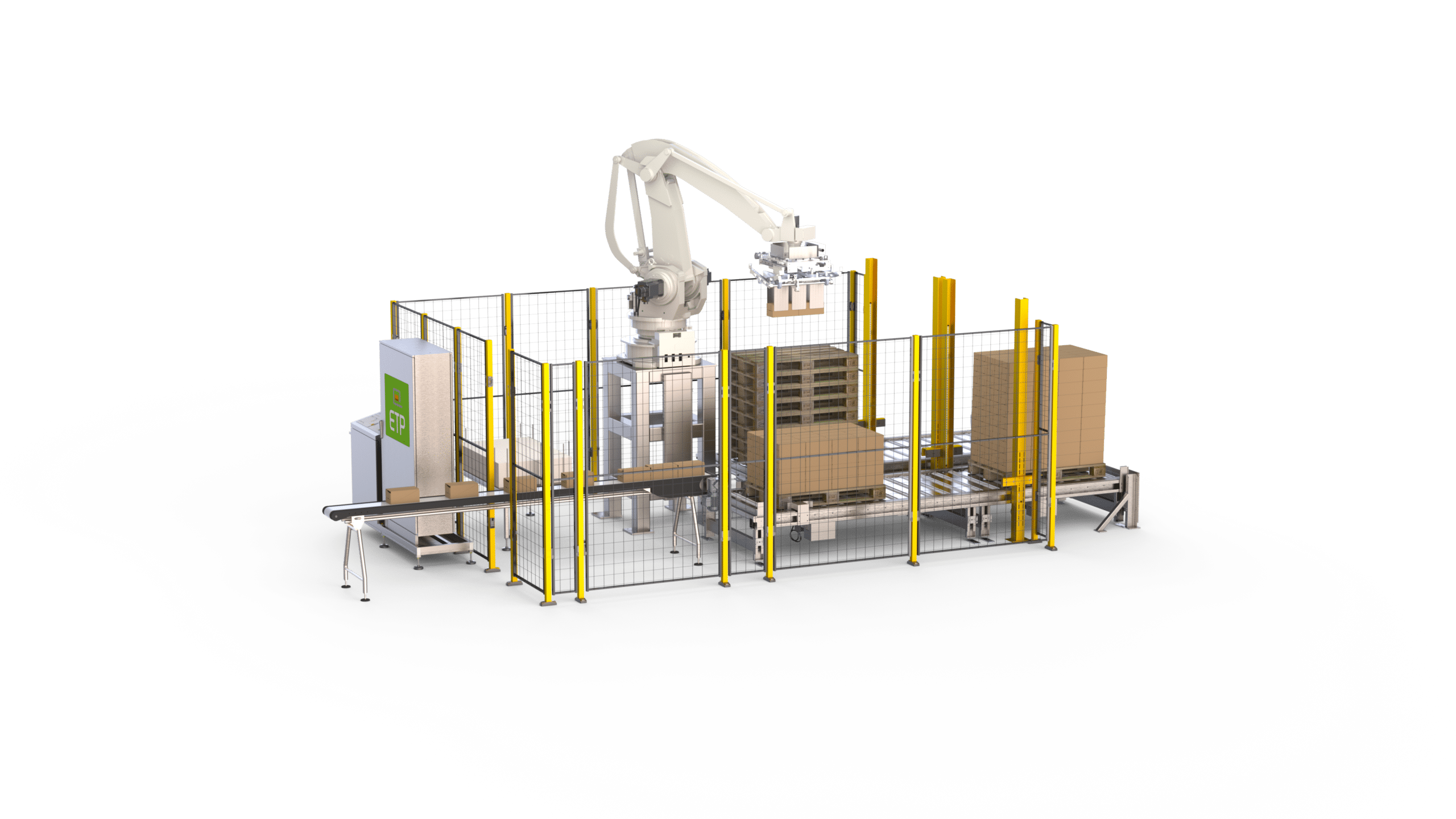

The palletising robot is controlled by an intuitive software interface, which enables palletising patterns to be configured according to the dimensions of the boxes or containers, the type of pallet used (EUR, half-pallet, etc.) and the desired height. Some models are capable of managing several lines in parallel or several product references, making them particularly well suited to complex industrial environments.

Finally, modern palletising robots are often coupled with automatic banding or labelling systems, creating a totally autonomous end-of-production line.

What products can a palletising robot handle?

A palletising robot is designed to adapt to a wide variety of formats and packaging. It can handle with the same precision :

- boxes of different sizes and weights,

- metal containerssuch as cans or industrial drums,

- glass containerswhich require great care when handling to avoid breakage.

Thanks to its sensors and adjustable gripping system, the palletising robot can identify the products, adapt its gripping force and position each item precisely. It is this adaptability which makes these machines a relevant choice in the agri-food, cosmetics, chemicals and logistics sectors.

The advantages of palletising robots

One of the great advantages of a palletising robot lies in its ease of use. Although the technology employed is cutting-edge, the user interface has been designed to enable operators to get to grips with it quickly. Touch screens, intuitive menus and assisted programming options mean that teams in the field can work autonomously.

In terms of safety, palletising robots comply with strict standards. It is often equipped with detection cells, from light curtains or even protective cages which guarantee safe operation for personnel, even in the event of a malfunction.

In terms of performance, the speed of palletisation is a powerful argument. Some palletising robots can stack up to several hundred parcels an hour, while maintaining perfect positioning. This level of reliability and speed enables companies to increase their responsiveness and reduce delivery times.

Request a quote for the installation of a palletising robot

Are you planning to modernise your production line with a palletising robot? Put your trust in ET PACK, specialists in end-of-line automation. Thanks to its recognised technical expertise and personalised support, ET PACK can offer you high-performance, reliable palletising robots tailored to your industrial constraints.

Our teams will design, sell, install and maintain your palletising robot, taking into account your volumes, product types and production targets. Each project is the subject of a detailed quotation and a tailor-made solution.

Don't wait any longer to improve your production rates, make your teams safer and optimise your logistics. Contact us now for a personalised quote and to find out how a palletising robot can transform your production.