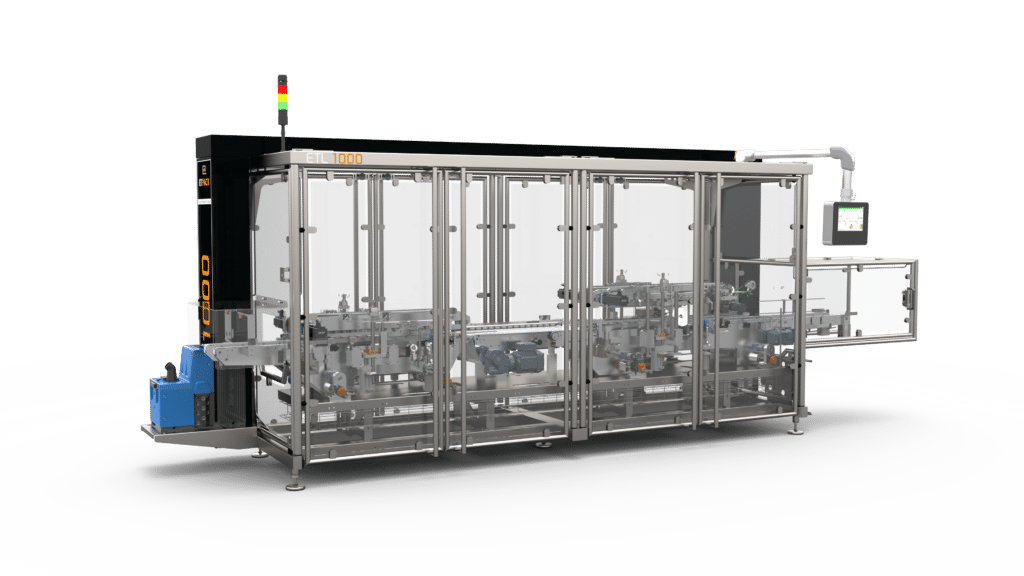

ETL1000 closer

GENERAL DESCRIPTION

- Automatic machine for closing 3-flap boxes by gluing

- In-line machine with gearboxes driven by vacuum and motorised belts

- Possibility of closing cardboard boxes from light-weight to micro-flute

- Multiformat machine

- Bonding using hot melt adhesive generators

- Automatic unitary correction of lid position before gluing to ensure perfectly squared closure of cans

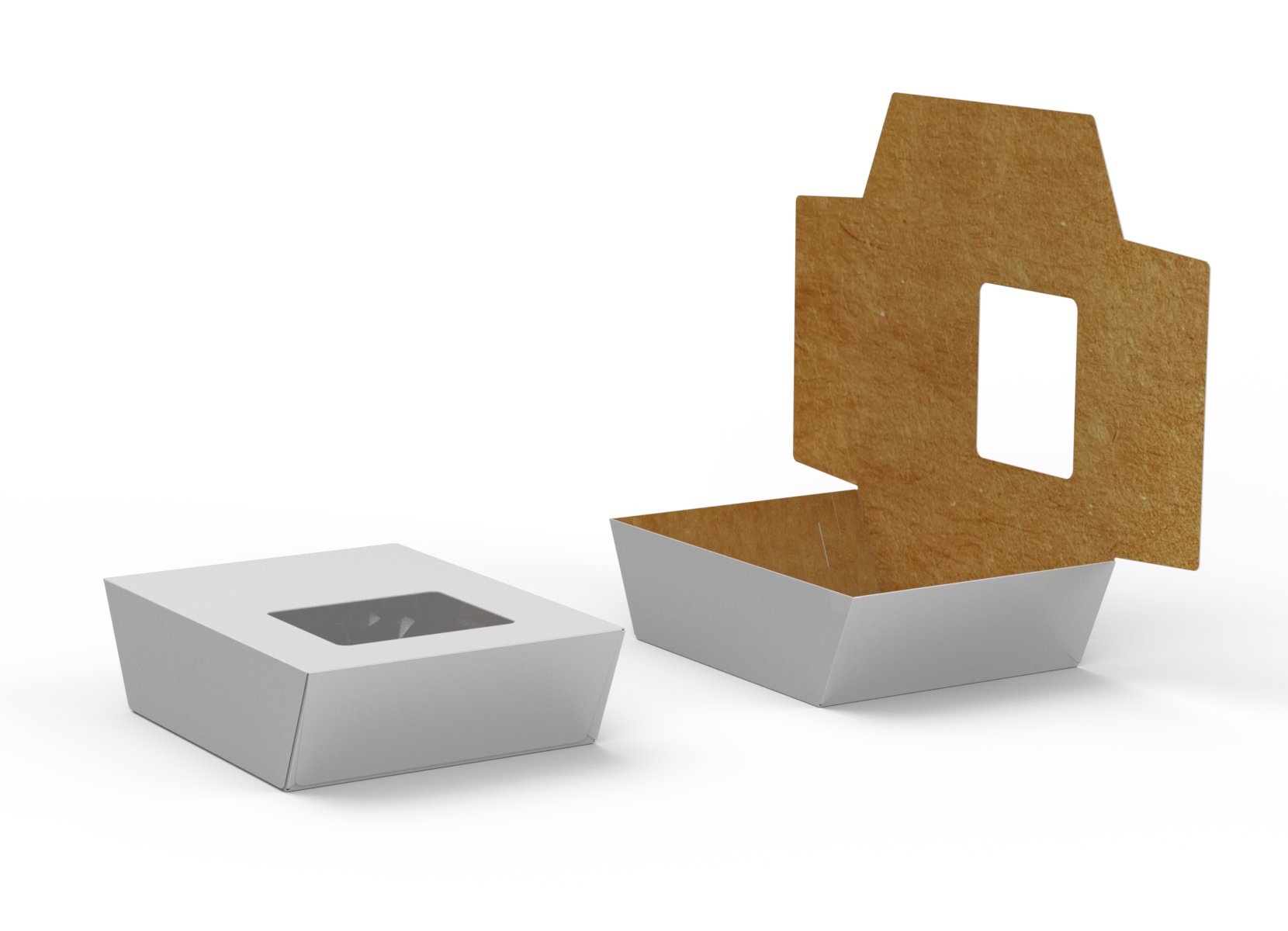

- Compact, micro-fluted cardboard

- Applications : Top-load cases with lid

- 3 flaps or 1 front flap

- Right or left-hand machine drive version

- Options: Extended output belts, control of unglued flaps, inkjet marker integration, etc.

TECHNICAL DATA

- Infeed conveyor for box separation and stop/start management stop

- First STEP for closing the cover using a motorised belt

- Positive turning by motorised starwheel

- Second STEP for closing side flaps

- 15.6' HMI on swivel arm

- Brushless motors

- Multi-brand Ethercat communication

- Stainless steel frame

- Dimensions: 1680 x 4055 x 1500 mm

- Classification: IP54

- Power supply: 17 kW

- Pneumatic supply: 6 bar

- Standard mini/maxi formats :

- Length: 100 - 300 mm

- Width: 85 - 300 mm

- Height: 20 - 100 mm

UP TO 150 BOXES/MIN

Additional information

| Machine speed | 10 to 160 cps/min |

|---|---|

| Final packaging | |

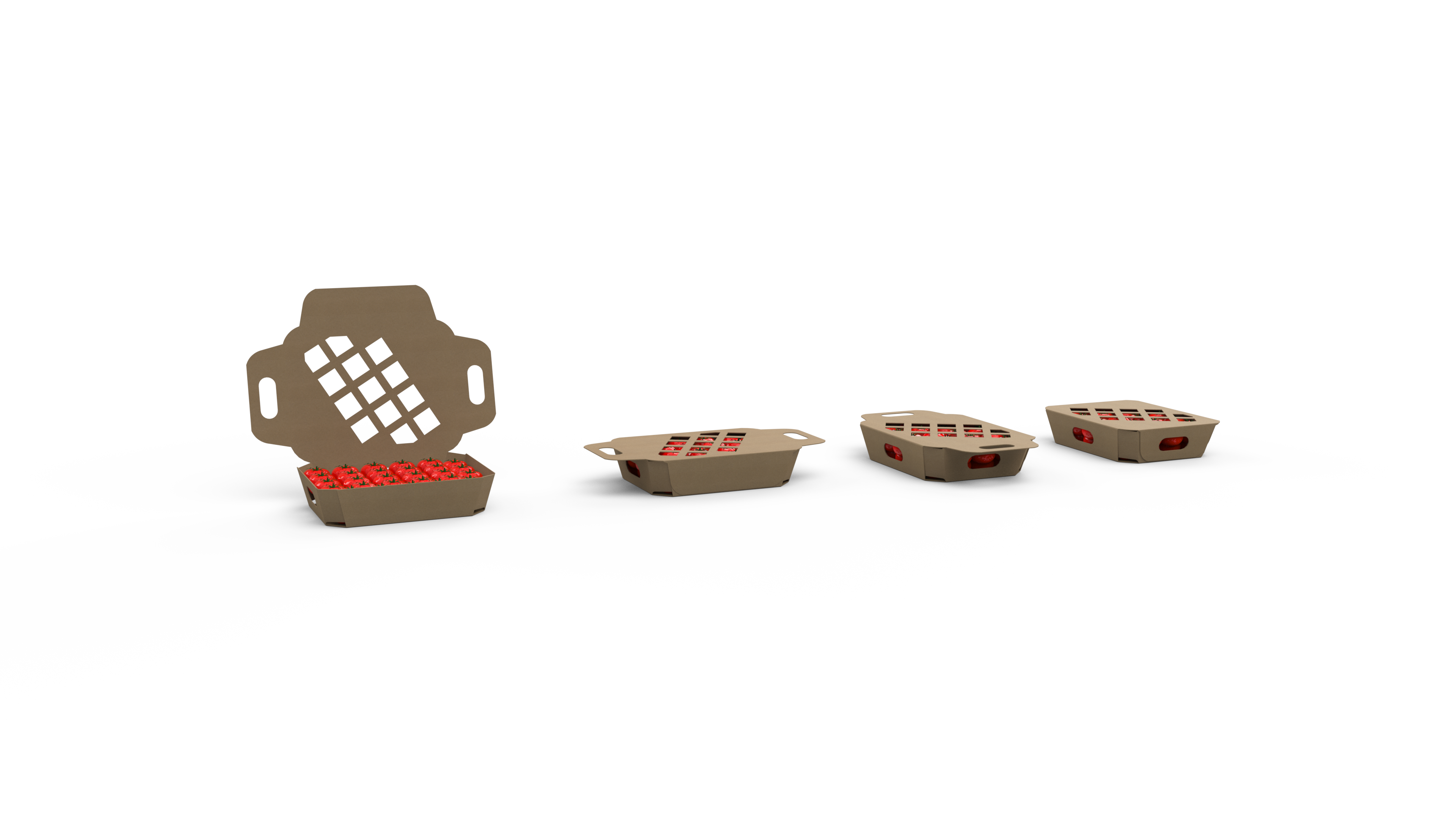

| Your product | Chocolaterie, Confectionery, Fruit and vegetables, Frozen products, Meat and poultry |

In the same range

Related products

-

ET300V vertical cartoner

- Secondary packaging, Cartoners, Automatic

- Output of up to 45 cartons/min

- Volume setting - filling from the top - closing

- Intermittent operation

- Discover

Machine speed Final packaging Your product -

Cartoning machine ET320

- Secondary packaging, Cartoners, Automatic

- Output up to 120 cartons/min

- Volume - filling - closing

- Continuous operation

- Discover

Machine speed 40 to 120 cps/min

Final packaging Cases

Your product Biscuits, Chocolate, Confectionery, Cosmetics and pharmaceuticals, Seafood, Frozen foods, Meat and poultry

-

Combi NORDIA

- Secondary packaging, Formers Top Load closers, Combi Top Load

- Output up to 100 cans/min

- Creating volume from a flat cut-out

- Bonding using hot-melt adhesive generators

- Discover

Machine speed 10 to 35 cps/min

Final packaging Top-Load box

Your product Chocolate, Confectionery, Fruit and vegetables, Frozen foods