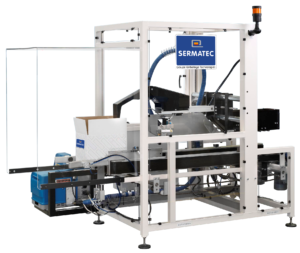

American box closer ETCA CS300

GENERAL DESCRIPTION

- The case will be taken over between the two sidebelts and transit the case through the machine

- The belts have a special profile, which keep the case under control during the transit of the case

- The front flap will first be pre-folded by the short flap folder mechanism before it will be closed. As soon as the back side of the case is located by a photo cell the back flap will be closed

- The flapfolders will fold the long flaps during transport

- Then the case will be sealed on top with tape, the closed case will be transported out of the machine

- The side adjustements from the sidebelts and the height adjustement can be done with hand-wheels

- The adjustements from both flap folders can be changed easily with one handle, the adjustements can easily be read from measure scales

- The tape sealer standard exists of a closing unit on top with tape. In the tape sealer the side belts keep the case perfect under control during taping of the top of the case

- Options : Warning beacon detection out of tape / tape broken; In feed guides (self adjusting); Discharge free detection by photocell; Minimum closed case height of 60mm / 80mm / 100mm; In feed guides with separation module and stopper; Check flap closed correct

TECHNICAL DATA

- Tape check out of tape / tape broken

- Transit control; when case crashes the machine will stop (time control)

- Control minimum distance between cases 350 mm

( when cases enter the machine against each other this functionality will not operate)

- Machine dimensions: 2660 x 975 x 1800 mm

104.72" x 38.39" x 70.87

- Pneumatic supply : 6 bars

- Mini/maxi cases dimensions:

- Length: 200 - 650 mm / 7.87 " - 25.59 "

- Width: 120 - 510 mm / 4,72 " - 20,08 "

- Height: 120 - 600 mm / 4,72 " - 23,62 "

UP TO 30 CASES/MIN

COMPACT & ERGONOMIC

Additional information

In the same range

Related products

-

Case packer ETC20

- Case packing, End of line, Pick&Place trays packer, Wraparound case packer

- Up to 20 cases/min

- Wrap-Around cartoning with hot-melt gluing

- Intermittent motion

- Discover

Machine speed Final packaging Your product -

American box formers ETC CA20

- American box formers, Case forming, End of line

- Up to 25 cases/min

- Carton packing of American cases by hot-melt gluing or by adhesive

- Intermittent motion

- Discover

Machine speed Final packaging Your product -

American box closer ETCA CS1000

- American box closers, Case forming, End of line

- Up to 30 cases/min

- American box closer by hot-melt gluing

- Intermittent motion

- Discover

Machine speed Final packaging Your product