Endload cartoner ET320

GENERAL DESCRIPTION

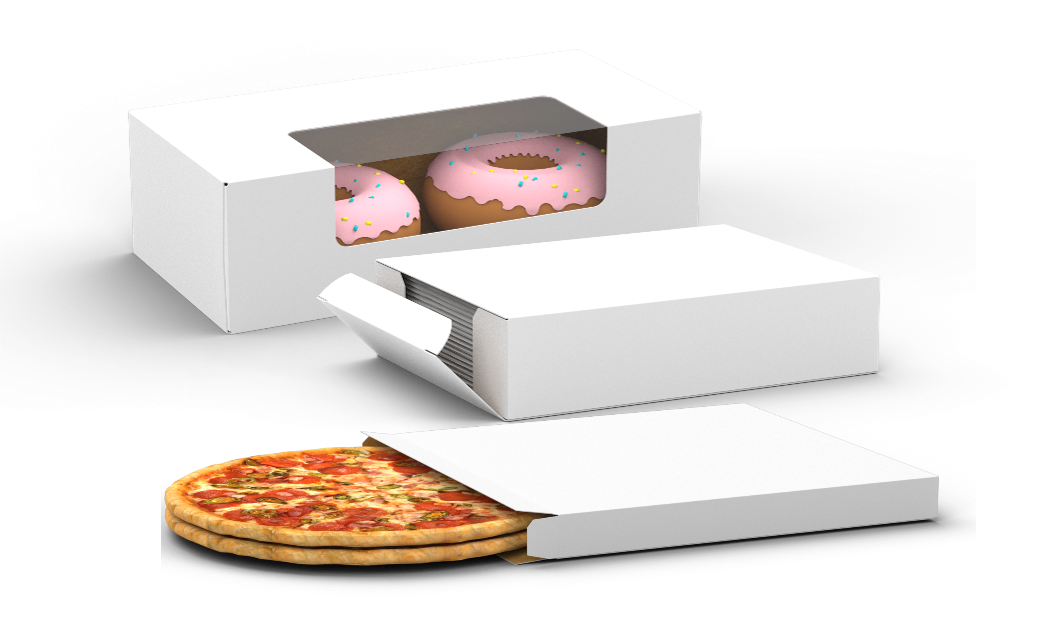

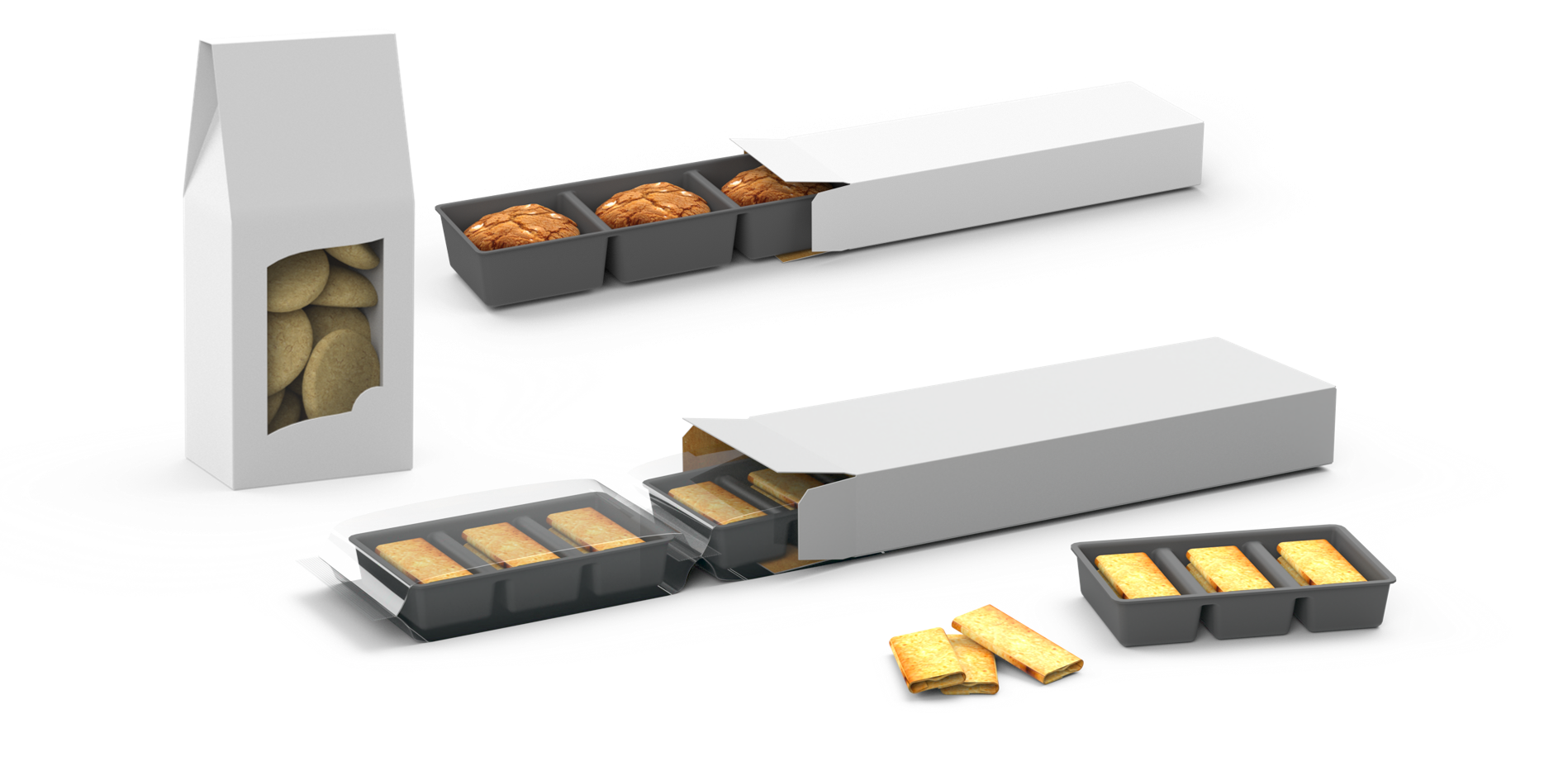

- Multiformat automatic endload cartoner for box forming, loading and closing

- Continuous motion

- Applications: boxes with or without window

- Dealing with cardboard as well as microfluted board

- Gluing by hot-melt glue melter

- A wide range of automatic infeeds: Unitary products, batching, stacking ...

- Options: in-going buckets conveyor, automatic settings, inkjet marker integration, label application, barcode control, control and rejection of not glued boxes ...

TECHNICAL DATA

- High capacity easy loading blanks magazine

- 4-arm rotary feeder

- Boxes pre-opening vacuum cups

- Push input 12 stations

- HMI up to 15,6''

- Servodriven motors

- Multi-brand Ethercat communication

- Stainless steel frame

- Dimensions: 6800 x 1550 x 2050 mm

267.72" x 61.02" x 81.71

- Classification: IP54

- Power supply: 18 kW

- Pneumatic supply: 6 bars

- Mini/maxi boxes dimensions:

- Length: 120 - 390 mm / 4.72" - 15.35

- Width: 40 - 320 mm / 1.57" x 12.60

- Height : 25 - 110 mm / 0,98 " x 4,33 "

VERSATILITY & EFFICIENCY

Up to 120 boxes/min

Additional information

| Machine speed | |

|---|---|

| Final packaging | |

| Your product | Biscuits, Chocolate factory, Confectionery, Convenience food, Cosmetics and pharma, Frozen products, Meat, Sea products |

In the same range

Related products

-

Wraparound cartoner ECOWRAP® ETW204

- Bottom gluing, Secondary packaging, Wraparound cartoner ECOWRAP®

- Up to 200 packs/min

- Sleeving or lid positioning from a flat blank

- Continuous motion

- Discover

Machine speed Up to 200 packs/min

Final packaging Lid, Sleeves

Your product Chocolate factory, Confectionery, Convenience food, Dairy product, Fruits & Vegetables

-

Endload cartoner ET300R

- Automatic, End load cartoner, Secondary packaging

- Up to 65 boxes/min

- Box forming - loading- closing

- Intermittent motion

- Discover

Machine speed Up to 60 ppm

Final packaging Boxes

Your product Biscuits, Chocolate factory, Confectionery, Convenience food, Cosmetics and pharma, Frozen products, Sea products

-

Endload cartoner ET300P

- Automatic, End load cartoner, Secondary packaging

- Up to 40 boxes/min

- Box forming - loading - closing

- Intermittent motion

- Discover

Machine speed Up to 40 ppm

Final packaging Boxes

Your product Biscuits, Chocolate factory, Confectionery, Convenience food, Cosmetics and pharma, Frozen products, Meat, Sea products