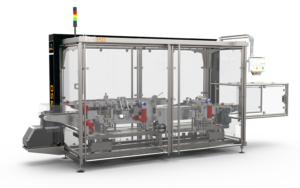

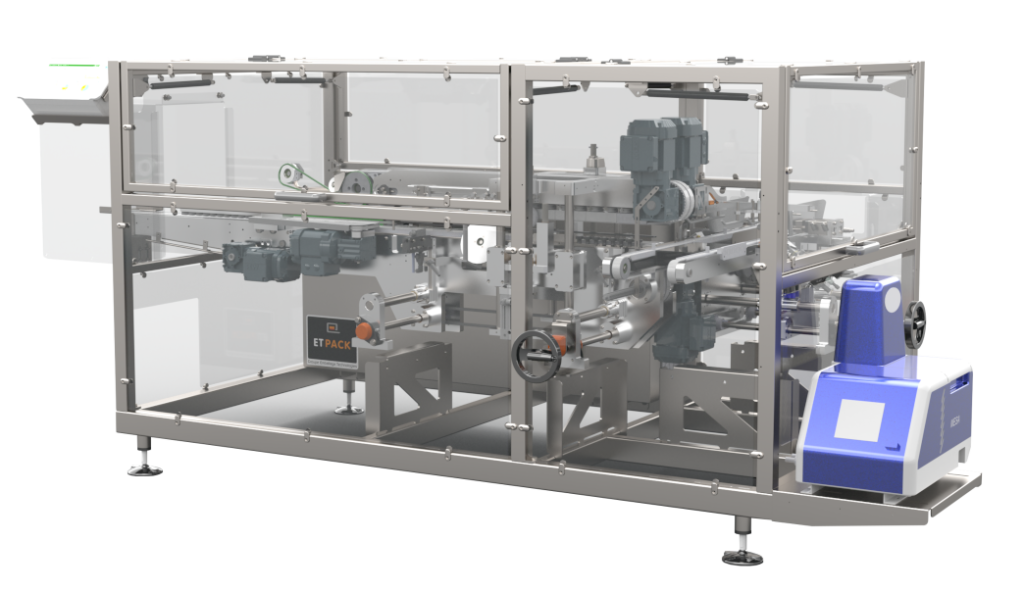

Box closer ETL400

DESCRIPTIF GÉNÉRAL

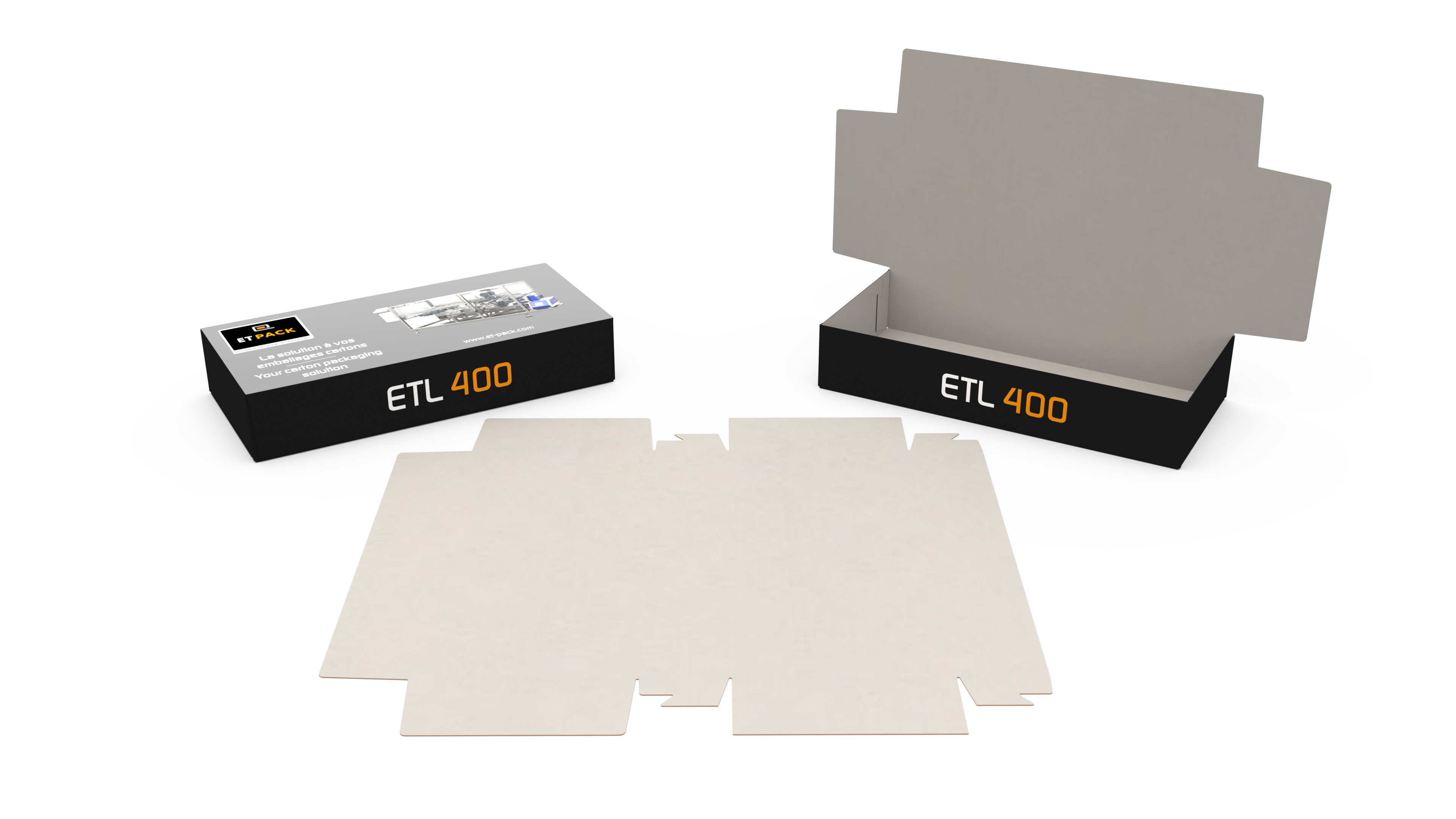

• Hot-melt gluing box closing machine with integrated 90° transfer

• Dealing with cardboard as well corrugated board

• Applications: Top-load three-flap cases with attached lid

• Right or left-hand machine drive version

• Multiformat box closer

• Continous operation

CARACTÉRISTIQUES TECHNIQUES

• Conveyor for timing and synchronization

• First STEP folding and gluing of the lid by motorized belt

• Second STEP of folding and gluing the side flaps

• Servodriven second step for side flaps closing

• 7′ color touch Human-Machine Interface

• Stainless steel frame

• Dimensions : 3200 x 1400 x 1430 mm

125.98′ x 55.19′ x 56.30′

• Power supply: 10 KW

• Air supply: 6 bars

• Mini/maxi packs sizes:

- Length: 85–300 mm / 3.35′ – 11.81′

- Width: 80–210 mm / 3.14′ – 8.27′

- Height: 30–80 mm / 1.18′ – 3.14′

Up to 40 boxes/min

RELIABLE & COMPACT

Informations complémentaires

| Cadence machine | |

|---|---|

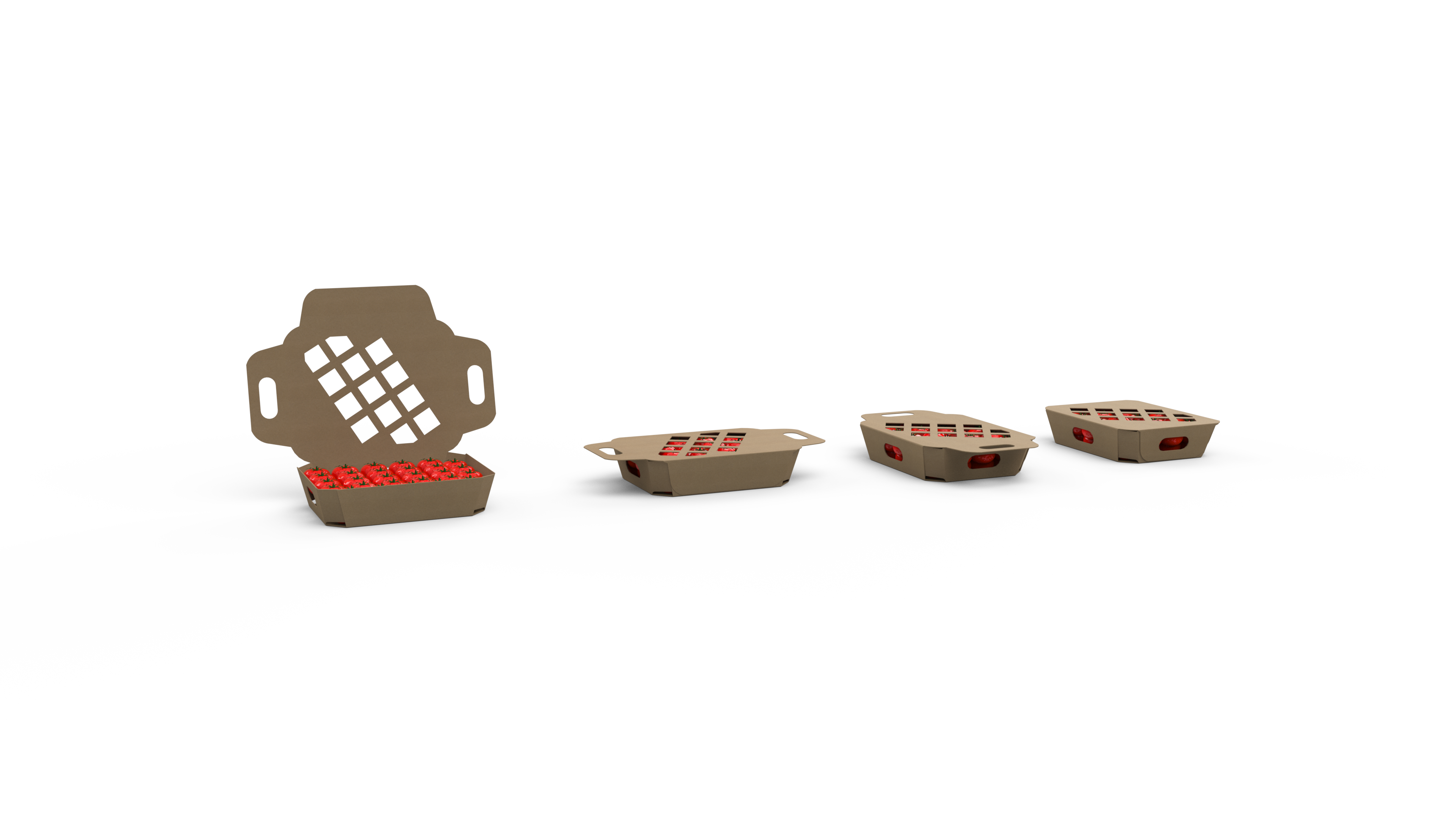

| Emballage final | |

| Votre produit | Biscuits, Chocolate factory, Confectionery, Convenience food, Frozen products, Fruits & Vegetables, Meat |

Dans la même gamme

Produits similaires

-

Formers ETL60-V

- Carton forming, Looking, Secondary packaging, Top Load Formers & Closers

- Up to 60 boxes/min

- Box forming from a flat blank

- Forming by locking

- Découvrir

Cadence machine Up to 60 ppm

Emballage final Boxes

Votre produit Biscuits, Chocolate factory, Convenience food, Frozen products, Fruits & Vegetables, Meat, Sea products

-

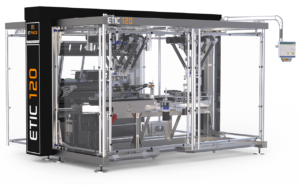

ENDLOAD CARTONER ETIC120

- End load cartoner, Robotic, Secondary packaging

- Up to 120 boxes/min

- Box forming – loading- closing

- Intermittent and continuous motion

- Découvrir

Cadence machine Emballage final Votre produit -

Box closer ETL350

- Carton closing, Secondary packaging, Top Load Formers & Closers

- Up to 80 boxes/min

- Box closer

- Closing by hot-melt

- Découvrir

Cadence machine Emballage final Votre produit