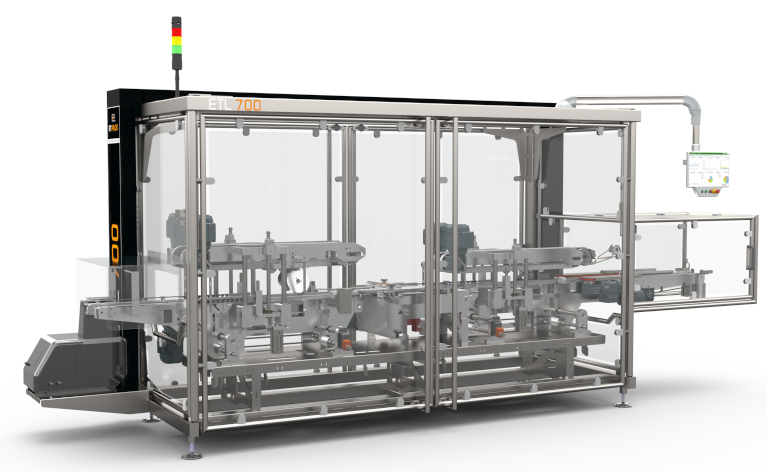

Box closer ETL700

DESCRIPTIF GÉNÉRAL

• Multiformat box closer

• Closing by hot-melt or tuck-in

• Servodriven turning section

• Dealing with cardboard as well as micro-fluted

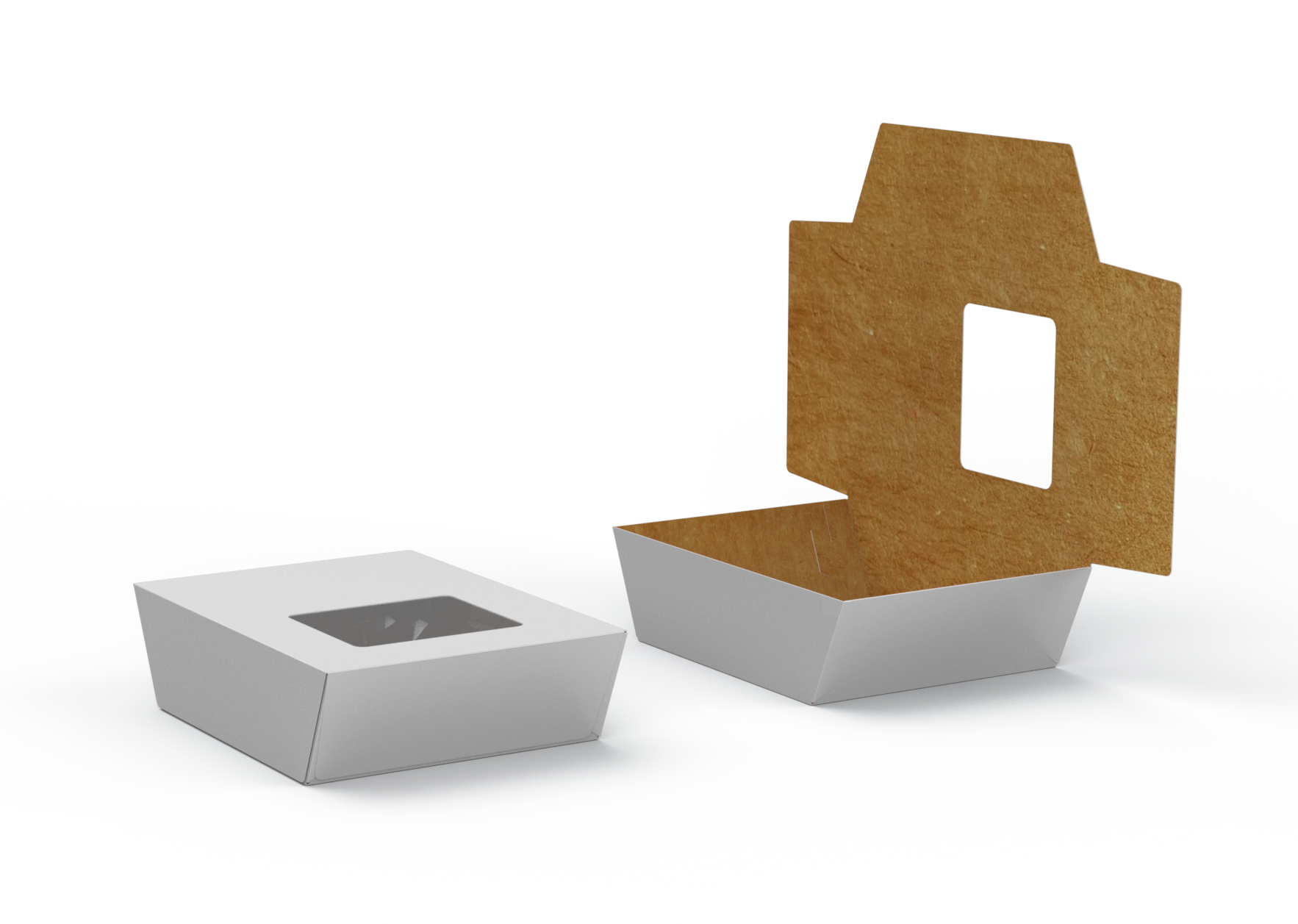

• Applications: Boxes with lid

• 3 flaps or 1 front flap

• Right or left-hand drive version

• Options: control and rejection of not glued boxes , inkjet marker integration, etc.

CARACTÉRISTIQUES TECHNIQUES

• Infeed conveyor for boxes gating

• Servodriven first step for lid and front flap closing

• Servodriven turning section

• Servodriven second step for side flaps closing

• HMI up to 15,6’’

• Brushless motorization

• Multi-brand Ethercat communication

• Stainless steel frame

• Dimensions: 4200 x 1300 x 2050 mm

• Classification: IP54

• Electrical power supply: 6 kW

• Pneumatic power supply: 6 bars

• Standard minimum/maximum formats:

-

- Length: 100 – 310 mm

- Width: 85 – 310 mm

- Height: 20 – 150 mm

Up to 80 boites/min

Informations complémentaires

| Cadence machine | |

|---|---|

| Emballage final | |

| Votre produit | Biscuits, Chocolate factory, Confectionery, Convenience food, Frozen products, Fruits & Vegetables |

Dans la même gamme

Produits similaires

-

Wraparound cartoner ECOWRAP® ETW204

- Secondary packaging, U Shape, Wraparound cartoner ECOWRAP®

- Up to 200 packs/min

- Sleeving or lid positioning from a flat blank

- Continuous motion

- Découvrir

Cadence machine Up to 200 packs/min

Emballage final Lid, Sleeves

Votre produit Chocolate factory, Confectionery, Convenience food, Dairy product, Fruits & Vegetables

-

Formers ETL70-G

- Carton forming, Gluing, Secondary packaging, Top Load Formers & Closers

- Up to 90 boxes/min

- Box forming from a flat blank

- Hot-melt gluing

- Découvrir

Cadence machine Up to 90 ppm

Emballage final Boxes

Votre produit Biscuits, Chocolate factory, Convenience food, Frozen products, Fruits & Vegetables, Meat, Sea products

-

Endload cartoner ET300R

- Automatic, End load cartoner, Secondary packaging

- Up to 65 boxes/min

- Box forming – loading- closing

- Intermittent motion

- Découvrir

Cadence machine Up to 60 ppm

Emballage final Boxes

Votre produit Biscuits, Chocolate factory, Confectionery, Convenience food, Cosmetics and pharma, Frozen products, Sea products