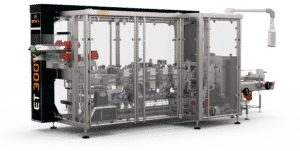

Endload cartoner ET300MC

DESCRIPTIF GÉNÉRAL

• Multiformat endload cartoner for closing by gluing

• Dealing with cardboard as well as microfluted

• Continuous motion

• Applications: All products to be put in boxes

• Options: inkjet marker integration, extended infeed conveyor

CARACTÉRISTIQUES TECHNIQUES

• Integrated electrical cabinet

• Connexion on mains socket

• Variable speed

• Torque limiter on infeed conveyor

• Stainless steel frame on wheels

• Dimensions : 1270 x 805 x 1230 mm

50 » x 31,69 » x 48,43

• Classification : IP54

• Power supply: 5kW

• Air supply: 6 bars

• Mini/maxi formats :

-

- Length : 100 – 320 mm / 3,94 » – 12,6 »

- Width : 80 – 340 mm / 3,15 » – 12,6 »

- Height : 20 – 80 mm / 0,79 » – 3,15 »

Small footprint, mobile & versatile

Up to 30 boxes/min

Informations complémentaires

| Cadence machine | |

|---|---|

| Emballage final | |

| Votre produit | Biscuits, Chocolate factory, Confectionery, Convenience food, Cosmetics and pharma, Frozen products, Meat, Sea products |

Dans la même gamme

Produits similaires

-

VERTICAL ENDLOAD CARTONER

- Automatic, End load cartoner, Secondary packaging

- Up to 45 boxes/min

- Box forming – loading – closing

- Intermittent motion

- Découvrir

Cadence machine Emballage final Votre produit -

Formers ETL60-V

- Carton forming, Looking, Secondary packaging, Top Load Formers & Closers

- Up to 60 boxes/min

- Box forming from a flat blank

- Forming by locking

- Découvrir

Cadence machine Up to 60 ppm

Emballage final Boxes

Votre produit Biscuits, Chocolate factory, Convenience food, Frozen products, Fruits & Vegetables, Meat, Sea products

-

Endload cartoner ET300R

- Automatic, End load cartoner, Secondary packaging

- Up to 65 boxes/min

- Box forming – loading- closing

- Intermittent motion

- Découvrir

Cadence machine Up to 60 ppm

Emballage final Boxes

Votre produit Biscuits, Chocolate factory, Confectionery, Convenience food, Cosmetics and pharma, Frozen products, Sea products