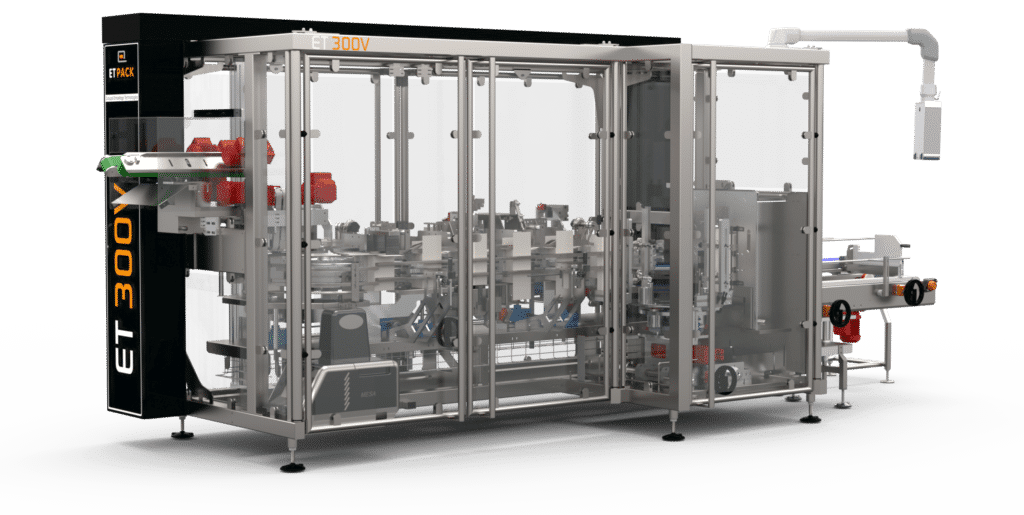

VERTICAL ENDLOAD CARTONER

DESCRIPTIF GÉNÉRAL

• Multiformat intermittent motion vertical endload cartoner enabling carton forming, top filling, and closing

• Applications : flexible bags, bulk products …

• Boxes with or without window

• Cardboard as well as microfluted

• Hot-melt gluing or tuck-in

• Manual infeed, automatic with by-pass function, or robotic

• Quick and easy format changeover

• Options : inkjet marker integration, label application, barcode control, control and rejection of not glued boxes …

CARACTÉRISTIQUES TECHNIQUES

• Ergonomic, high-capacity horizontal magazine

• Rotary 2- to 4-arm feeder with positive opening suction cups

• Modern linear belt indexer enabling precise, repeatable, and controlled movement of cartons from one workstation to another

• Product compacting system and product top control

• Ethercat communication

• Stainless steel frame

• Dimensions : 3450 x 1745 x 1425 mm

135,83’’x 68,70’’x 56,10’’

• Power supply : 22 kW

• Air supply : 6 bars

RELIABILITY & FLEXIBILITY

Up to 45 boxes/min

Informations complémentaires

Dans la même gamme

Produits similaires

-

Wraparound cartoner ECOWRAP® ETW204

- Bottom gluing, Secondary packaging, Wraparound cartoner ECOWRAP®

- Up to 200 packs/min

- Sleeving or lid positioning from a flat blank

- Continuous motion

- Découvrir

Cadence machine Up to 200 packs/min

Emballage final Lid, Sleeves

Votre produit Chocolate factory, Confectionery, Convenience food, Dairy product, Fruits & Vegetables

-

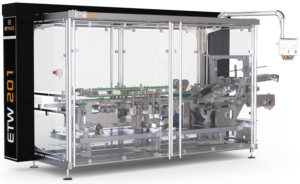

Wraparound cartoner ECOWRAP® ETW201

- Secondary packaging, U Shape, Wraparound cartoner ECOWRAP®

- Up to 80 packs/min

- Sleeving or lid positioning from a flat blank

- Continuous motion

- Découvrir

Cadence machine Up to 80 pack/min

Emballage final Lid, Sleeves

Votre produit Chocolate factory, Confectionery, Convenience food, Dairy product, Fruits & Vegetables

-

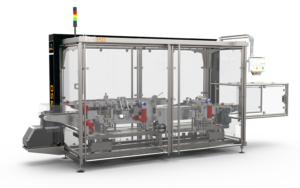

Box closer ETL350

- Carton closing, Secondary packaging, Top Load Formers & Closers

- Up to 80 boxes/min

- Box closer

- Closing by hot-melt

- Découvrir

Cadence machine Emballage final Votre produit