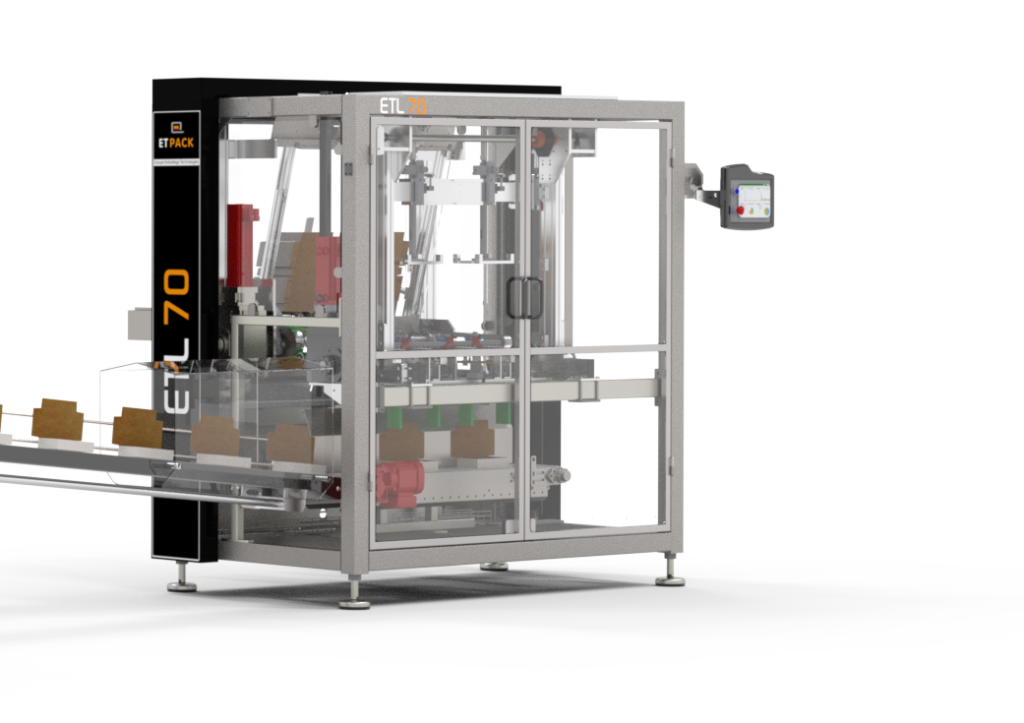

Formers ETL70-V

DESCRIPTIF GÉNÉRAL

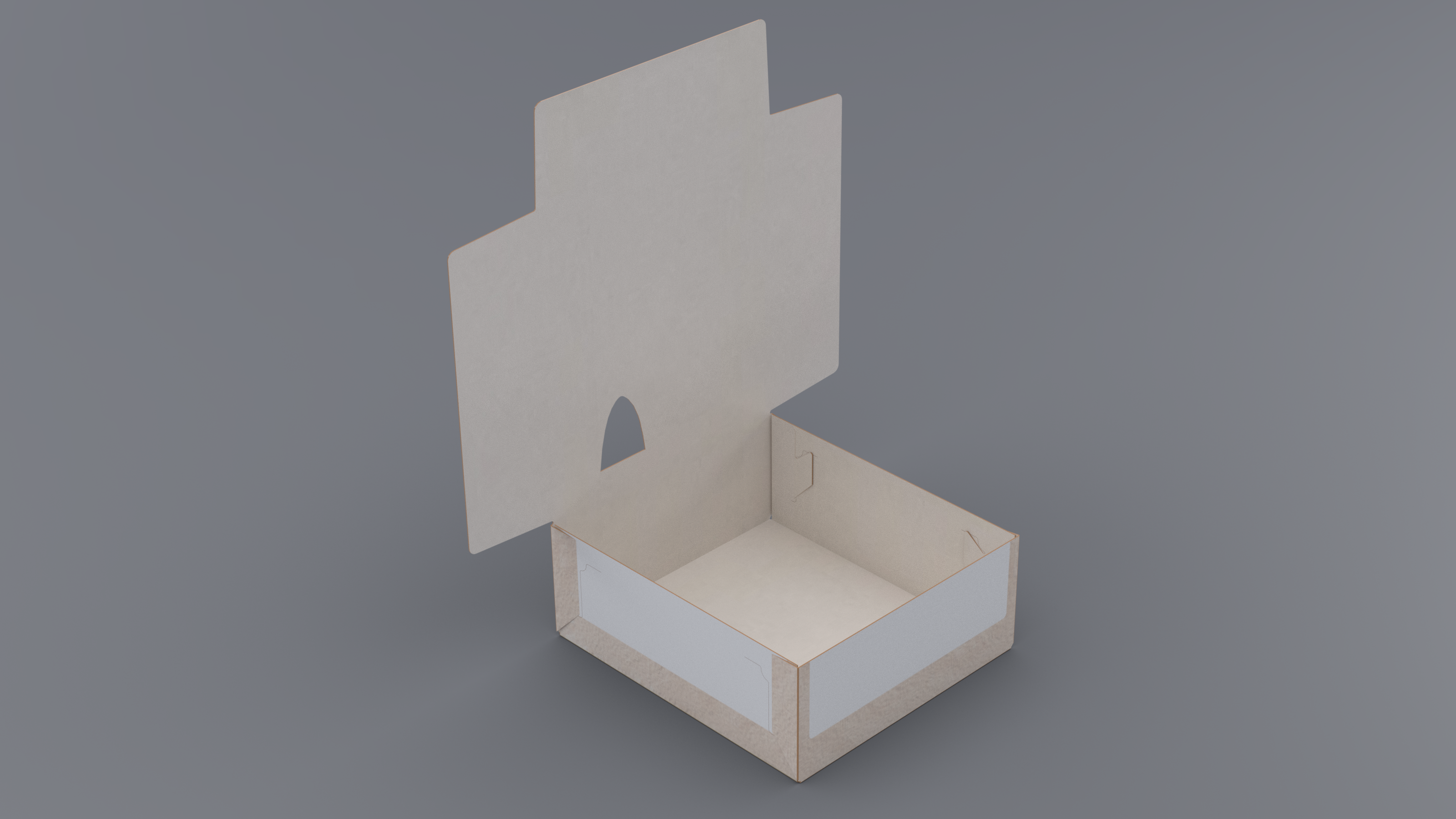

• Box forming from a flat blank

• Forming by locking

• Dealing with cardboard as well as micro fluted board

• For trays, boxes with lid, dust-flaps box, with or without conicity, trays or punnets…

• Up to 3 heads

• Multiformat stainless steel machine

CARACTÉRISTIQUES TECHNIQUES

• Pendular feeder with vacuum cups

• Direct transfer of blanks

• High capacity easy loading magazine

• Interchangeable toolsets

• Axis controller and servodriven motors

• Stainless steel frame

• Dimensions : 1950 x 1620 x 2000 mm

76,77’’ x 43,31’’ x 78,74’’

• Classification : IP54

• Power supply: 8 kW

• Pneumatic supply: 6 bars

• Mini/maxi boxes dimensions :

- Length : 90 – 480 mm / 3,54’’ – 18,90’’

- Width : 65 – 210 mm / 2,56’’ – 8,27’’

- Height : 20 – 90 mm / 0,79’’ – 3,54’’

UP TO 130 BOXES/MIN

ACCURACY & SQUARENESS

Informations complémentaires

| Cadence machine | |

|---|---|

| Emballage final | |

| Votre produit | Biscuits, Chocolate factory, Convenience food, Frozen products, Fruits & Vegetables, Meat, Sea products |

Dans la même gamme

Produits similaires

-

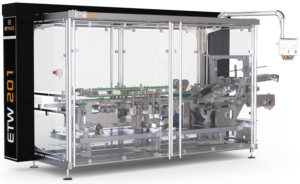

Wraparound cartoner ECOWRAP® ETW201

- Bottom gluing, Secondary packaging, Wraparound cartoner ECOWRAP®

- Up to 80 packs/min

- Sleeving or lid positioning from a flat blank

- Continuous motion

- Découvrir

Cadence machine Up to 80 pack/min

Emballage final Lid, Sleeves

Votre produit Chocolate factory, Confectionery, Convenience food, Dairy product, Fruits & Vegetables

-

Wraparound cartoner ECOWRAP® ETW201

- Secondary packaging, U Shape, Wraparound cartoner ECOWRAP®

- Up to 80 packs/min

- Sleeving or lid positioning from a flat blank

- Continuous motion

- Découvrir

Cadence machine Up to 80 pack/min

Emballage final Lid, Sleeves

Votre produit Chocolate factory, Confectionery, Convenience food, Dairy product, Fruits & Vegetables

-

Endload cartoner ET180

- Automatic, End load cartoner, Secondary packaging

- Up to 200 boxes/min

- Box forming – loading- closing

- Continuous motion

- Découvrir

Cadence machine Up to 200 ppm

Emballage final Boxes

Votre produit Biscuits, Chocolate factory, Confectionery, Convenience food, Cosmetics and pharma, Frozen products, Sea products